I had Fox frame and forend iron annealed and have scalloped reshaped frame and restocked the gun.I have read and heard that gun should not be used without having rehardened.Anyone had any experience with this? Thanks,Bobby

Bobby,

I'd have it re-casehardened before use. Will it damage it if you shoot a box of light loads? I doubt it.

I have a customer who likes to shoot his guns in on a custom stock. We are doing a Parker upgrade currently and he shot it for POI in it's annealed state. No harm done. I would recommend keeping it to a minimum.

On line with Bobby's question, I have an field grade Ithaca someone did a whole lot of very fancy engraving on and then, I think, blued. I suspect it was annealed to allow for all the engraving and that it was never re-cased since it was blued.

How can I tell if it was re-cased? For whatever its worth to Bobby, I've been shooting the gun with Bismuth Classic which I don't think is particularly low pressure and have not noticed any problems...Geo

the purpose of hardening shotgun parts is to increase the life of those parts at their wear points. seems like working the action of a gun without hardening it's working parts would cause those parts to wear out sooner than later?

Frames on vintage double guns were originally case hardened at the factories for a reason.

Annealing brings the steel back to its pre-hardened softness. Shooting an annealed gun will likely lead to premature wear on the bearing surfaces and cause the action to go loose before its time. Surface dents, dings and scratches are also more likely to occur. For those who've ever filed or sanded hardened and annealed steel, the difference between the two is remarkable. If you intend to shoot it, have it rehardened. If you don't like case colors, they can easily be brushed off to enhance the engraving.

the purpose of hardening shotgun parts is to increase the life of those parts at their wear points. seems like working the action of a gun without hardening it's working parts would cause those parts to wear out sooner than later?

The case hardening of the receiver makes it act like a spring. Otherwise it bends and stays bent.

Best,

Mike

I have serious doubts that case-hardening gives much of a spring effec to a piece of steel. After the case-hardening process if there was warpage etc, these gns were "HardFit". This meant they were bent back into shape. I do not believe that in this hard fitting they were moved enough they would not have gone back had they had a spring temper, but they stayed bent, indicating they were not of the nature of a spring.

Thanks to all.I may test fire it.George when you put a file to case hardened metal it will hardy cut. Bobby

I have serious doubts that case-hardening gives much of a spring effec to a piece of steel. After the case-hardening process if there was warpage etc, these gns were "HardFit". This meant they were bent back into shape. I do not believe that in this hard fitting they were moved enough they would not have gone back had they had a spring temper, but they stayed bent, indicating they were not of the nature of a spring.

Case hardening affects maybe a surface depth in mild (AISI 1018) forged parts like receivers of 0.0025"- annealing affects the entire area, but remember, whenever you subject a formed metal part to heat input, it flows towards the thinner sections- all the great American made side-by-sides (except the Winchester M21) were "double fitted"-- first in the pre-case hardening state (soft fitted) and then final or hard fitting after case hardening-- The great Parker authority now the late Edward Muderlak discloses this quite well in his book on Parkers, and even shows fotos of the late Dr. Oscar Gaddy with his furnace and chill box-

I have seen how well fitted the AH Fox guns are from my Sterlingworths- I would agree with the other gent who posted here- I would have the gun re-case hardened by someone who really knows what they are doing--

The case hardening of the receiver makes it act like a spring. Otherwise it bends and stays bent.

Best,

Mike

Say whO...

As shallow as case harding is I figured it was done more to protect the engraving.

There are plenty of guys [most} who had receiver of Fox, Parker etc recased and all they got are fancy colors. Has anyone ever heard of any modern case hardening shops sending a test strip of similar steel back with the receiver, along with information on case depth - penetration? Modern recasing is like picking the color of your new car without checking if theres an engine under the hood.

Old receivers were (are) made of mild steel (think carbon alloy content below 0.4%). They will not through heat harden under any circumstance. They are easy to case harden and to get case colores on. The case, as mentioned, is very thin and contributes little, if anything useful, to deflection strength. All steel (all metal, for that matter) parts will act as a spring until their yield points are exceeded. Through hardened steel parts make springs that will stand more strain (think deflection) than soft steel. I doubt that the case layer will add anything to a steel part acting like a spring. However, the case will reduce wear on "bearing" parts/surfaces. And, it will add a lot to corrosion resistance (high carbon steel is much more corrosion resistant than is mild steel).

The parts we usually worry about wearing are the hook, hinge pin, barrel lugs/rib extensions, and bolt(s). These are not usually cased. The breach face and action knuckle might benefit from case layer wear resistance. However, both areas are low pressure and low speed bearings during action cycling that are easy to keep well lubed.

I believe it was/is somewhat common for Brit bespoke gun customers to take their new guns shooting before engraving and hardening to be sure they were satisfied while alterations were still relatively easy to make.

DDA

Rocket, you cautioned me some time ago about the possible lack of re-casing of the blued frame on the Ithaca NID I mentioned in an earlier post to this thread. I've worried about that ever since, but I have been shooting ducks using hard kicking Bismuth shells for a couple of years and don't notice any damage.

Here's a picture of the frame. You noticed the gap at the knuckle on this gun. It hasn't gotten any worse as far as I can tell.

Bobby suggested trying a file on the frame to determine hardness. I did that but don't have enough experience filing on guns to tell whether its re-cased or not...Geo

The case, as mentioned, is very thin and contributes little, if anything useful, to deflection strength.

DDA

Well, as I try to remember where I got that information, the skin aluminum on a monocoque fuselage is very thin in relation to the cross section of the fuselage but adds tremendous resistance to both torquing and bending of the fuselage. I remember when I read the article that that was the conclusion that I came to. And apparently the low carbon frame doesn't need much stiffening as the Winchester 21 action steel is only about double strength of the low carbon steel but doesn't require case hardening.

I wonder what the difference in hardness is between the 21 steel and unhardened low carbon steel? I bring this up because of the contention that receivers are case hardened primarily to resist wear, say between the knuckle and the iron, which of course should be lubricated and have no wear.

"The case, as mentioned, is very thin and contributes little, if anything useful, to deflection strength."

I do not agree with that statement. It is inconceivable to me that all the pre-WWII makers would have bothered with the difficult and costly case hardening of their doubles if that were true. Especially during the depression years, when cutting overhead was paramount for companies to reduce costs and stay in business.

Shooting an annealed gun more than a few times is just asking for trouble. That being said, just because a gun has had its frame blued does not necessarily mean that it was annealed. It is probably far more likely that the case colors were brushed off and then it was blued. Rusting agents will work just fine on a hardened frame.

If a case hardened receiver is annealed, is it the whole receiver or just the thin hard case that can even be annealed. Didn't case hardening come about because the iron or very low carbon steel that was readily available, could not harden on it's own.

Also could be that if a receiver is permanently bent, it was deflected to a point that was exactly the same regardless of how hard it was. It may be that a classic receiver that was unable to harden, except for the created case, was less likely to crack than a through hardened receiver. Maybe?

OK, lets do a wee bit of metalurgy. Anyone with differing information is most welcome to step right into this. I'm not nterested in being right, rather that we all know the truth.

Steel changes modulus very little due to hardening. Modulus is the amount of strain (movement/deflection) you get for a certain stress (applied force). Hardened steels simply have a higher yield point. Example: if I made two identical springs from "soft" and "hard" steel, they would behave almost identically as springs until the "soft" one was deflected beyond its yield point. The "soft" one would now be permanently bent (dimensions altered) while the hard one would return to original dimensions. Now, same scenario except we case harden the "soft" one. Again, almost identical behaviour until we strain the "soft" one past the core's yield point. At that time, the core is bent and the case is trying to return the core to original dimensions. Calculate the difference in strength between the core and case shell and you will know the amount of influence the case shell can have. Now, think of the action as the spring. Many times over the amount of metal in the core as in the case shell!! Post if you don't follow that logic or disagree.

Shotgun actions were designed and developed (cut and try) using mild steel. It was what was available, more or less easy to work, reasonably priced, and workable sections met weight and strength requirements easily. The metal industry was used to case hardening - SOP. The difference in surface wear and corrosion resistance (think heavy shooting days in damp 'ole UK with black powder and no modern oils or cleaners) between a "soft" steel surface and a case shell surface is remarkable. So, it was relativly a small jump to case harden actions. CCH was a byproduct and not even used intentionaly early on.

Clearly, a "soft" receiver with a case shell is better than a through hardened receiver that is sufficintly brittle to be prone to cracking. Case hardened "soft" receivers were plenty good, so there iwas little push to develop a through hardened receiver. Modern steel alloys and machining techniques have, of course, changed this picture.

DDA

AmarilloMike,

I was once told by the manager of the M21 custom shop (Bruno Pardee)that their specifications for the M21 frame called for Rockwell 42 to 48 but that they tried to keep them about 42 so they could be engraved. Anything over 37 starts to be difficult to engrave which is why most engravers bemoan the hardness of the 21. I have engraved a few for the custom shop in the 80s and early 90s 'till they closed and they took a good bit more time to cut than other guns because of the excessive tool breakage. Ditto for M70 actions.

I do not know what mild steel measures in hardness but would guess in the 20s to maybe the low 30s.

Annealing older shotguns and recasing with no hardness but plenty of pretty colors was very common in the 90's. It avoided warping problems.

The guns suffered no mechanical problems from being in the soft/annealed condition till they were subjected to some real world use.

Sporting Clays and other target type shooters were having problems with galling parts. There was hardness needed in the very least at the knuckle of the frame and it's forend.

Even if no hardness is present,,the gun will perform nicely as a shotgun for the occasional shooter or hunter.

Give it some real use and it'll start showing up,,especially with a tightly fitted unit.

The rants over the Spanish shotguns of the 50's and 60's come much from the same problem. Soft steel improperly or not hardened at all.

I have in my shop a Greener FH35 that appears to have escaped the hardening process entirely. Either that or every part of it was annealed and left soft. The gun has obviously given years of good service and is still mechanically sound. Unfortunately all the engraved surfaces are worn down to the point of being barely discern able. Action, fore end iron, trigger plate top lever Deeley latch, trigger guard. It seems none the worse for wear but this seems to reinforce the argument that Hardening was more to protect the aesthetics rather than contribute strength.

Any budding engravers need a project??

OK, lets do a wee bit of metalurgy. Anyone with differing information is most welcome to step right into this. I'm not nterested in being right, rather that we all know the truth.

...if I made two identical springs from "soft" and "hard" steel, they would behave almost identically as springs until the "soft" one was deflected beyond its yield point. The "soft" one would now be permanently bent (dimensions altered) while the hard one would return to original dimensions....

Just for conversation, if identical in every way except for hardness, I believe that what ever point you compressed the soft spring to make it yield, that will also be the same point that the hardened spring yields. The hardened spring may require more force to get to that same deflection point, but that amount of deflection to permanent deformation will be the same for both springs. Probably, identical leaf springs would be a better example because a coil may compress to solid without yielding.

I believe receivers have been shown to spring when a gun is fired, but it seems to be related to design and the nature of the iron/very mild steel and not heat treatment to spring characteristics. We may be thinking along similar lines.

[quote=craigd Just for conversation, if identical in every way except for hardness, I believe that what ever point you compressed the soft spring to make it yield, that will also be the same point that the hardened spring yields. The hardened spring may require more force to get to that same deflection point, but that amount of deflection to permanent deformation will be the same for both springs. Probably, identical leaf springs would be a better example because a coil may compress to solid without yielding. [/quote]

Craig

your understanding is incorrect. Steel has a Young's modulus that is unchanged by heat treat.

The case hardening increases the yield strength. I agree that modulus of elasticity changes little.

But it is the yield strength that determines whether the frame bends or springs.

The case, as mentioned, is very thin and contributes little, if anything useful, to deflection strength.

DDA

Well, as I try to remember where I got that information, the skin aluminum on a monocoque fuselage is very thin in relation to the cross section of the fuselage but adds tremendous resistance to both torquing and bending of the fuselage. I remember when I read the article that that was the conclusion that I came to. And apparently the low carbon frame doesn't need much stiffening as the Winchester 21 action steel is only about double strength of the low carbon steel but doesn't require case hardening.

I wonder what the difference in hardness is between the 21 steel and unhardened low carbon steel? I bring this up because of the contention that receivers are case hardened primarily to resist wear, say between the knuckle and the iron, which of course should be lubricated and have no wear.

Double fitted 1018 case hardened American doubles- not quite the same as the single (hard) fitted M21 made of AISI 4140 nickel chromium molybdenum alloyed steel- but the M21 hit the drafting boards in New Haven in aprox 1926-1927 (some say the rumor extant then was- WRA tried to purchase Parker Brothers Gun business (not the entire Parker operation, which included hardware, hand tools and first rate vises)-- but that, IMO is a rumor, albiet perhaps a valid one-

Craig

your understanding is incorrect. Steel has a Young's modulus that is unchanged by heat treat.

Sorry Chuck, I thought that's what I was thinking. That elasticity is unchanged with hardness and both samples would permanently deform at the same point. If Young's modulus were followed, can you make the hardened sample deflect farther than the soft sample and return to true.

Craig

Since modulus (stiffness) is un changed with hardness the two springs will require the same force for the same deflection until the soft one reaches yells point. After that the hard spring will continue to require increased force until it reaches its yield or failure point.

Thanks for taking the time Chuck.

Craig

Sorry for the misspelling. Using a phone here. I hope I explained it well enough to be helpful.

Do we agree that the case shell is on the order of 0.002" thick (about the thickness of a human hair)? If so, and if the the "hard" shell had ten times the force per unit thickness trying to return the action to OE dimensions after yielding of the core, the first 0.020" of the "soft" section would balance the "hard" case shell. The "soft" has a whole lot more "meat" than does the "hard" shell.

Yep, a "soft" action will bend and spring back under firing stress. This is for the simple reason that the strain (deflection) does not exceed its yield strain. Note that stress and strain are somewhat interchangable as they are related in a very predictable way. X amount of stress will produce Y amount of strain. Y amount of strain indicates that the metal has X stress applied.

Good discussion!! Keep going until all understand.

DDA

One thing to keep in mind, most barralled actions in England...and other places by that matter go to the proof house before hardening, I think the vast majority pass proof.

This quote from David T's Technicana " at this point ,the gun...essentially a barrelled action with locks, fasteners, and ejectors but lacking triggers and a trigger plate, went back to the Proof House for definitive proof. Then it was ready for the stockmaker"

I would say if they can handle a few heavy proof loads it should be able to take some target loads...just don't overdo it, but it should be re-hardened at some point.

CJ

Yep, a "soft" action will bend and spring back under firing stress. This is for the simple reason that the strain (deflection) does not exceed its yield strain.

A "soft" action

can bend and spring back under firing stress as long as the strain (deflection) does not exceed its yield strain. If it does then the soft action will bend and stay bent.

Rocket I get your point about the .002" being very thin compared to the rest of the cross section of the action but I make the point again that the strength of a monocoque fusealage is primarily due to the thin skin held in place by bulkheads and runners. And the maximum tension strain is most likely at the surface, as is the maximum compression strain.

Don,

My non-statistical sample of cutting into a couple pieces of case hardened steel leads me to believe that while there is a uniformly hard layer of something like .002-008", there is also a gradient of hardness many times that. I base this on the machining of the steel and the observation of the finish. You can literally see the hardness gradient in terms of shineyness. I estimate that I've seen layers of gradient hardness up to .050". Or at least the gradients of shineyness up to that.

To be blunt and for the safety of the shooter, this Thread needs a short discourse in Metalurgy.

Case hardening and heat treating are too different processes designed to cause two different effects. Heat treating takes steel in its annealed state (annealing raises the temperature after forming to allow the stresses induced during forming to flow and 'anneal' which is actually an atomic process as 'dislocations' induced during forming actually flow to relieve themselves) which was designed to remove the stresses caused by forming and hardens the entire volume by raising the Tensile Stress. Prior to the use of high tensile steel by Winchester and Browning, shotguns were manufactured of lower tensile strength steel and as such the surfaces were not very hard to resist wear of both internal parts and the surface of the action. Case hardening was developed to harden the surfaces and the colors that resulted are a by product of the case process.

After the reciever of a shotgun is annealed for metal work, it is essential that it should both be heat treated correctly and the surface case hardebned properly for safety.

The receiver is probably safe to shoot as the design most likely will not cause catastrophic failure with a mild steel but should be done properly.-Dick

.

There are of course numerous processes which fall in the category of "Heat Treating", case hardening being one process in the broad category, IE it "IS" a heat treating process. In actuality, though often combined into a single operation, Case hardening is a two part process. The first step consists of "Carburizing" the low carbon steel to give the outer surface a higher carbon content. 2nd step is then to "Heat Treat" this carburized portion, thus the common name Case Harden.

The carburizing portion consists of bringing thr part to a temp above its critical temp & holding it there in the presence of a carbon rich atmophere for a time suitable to the desired penetration. The longer it is held the deeper the carbon penetrates though the deeper it gets the longer it takes for more depth, so there are practical limits which are not often exceeded.

The Heat treating portion is simply to quench the part in a suitable medium, usually water here, from a tamp above its critical temp. Since the part is already above this temp in the carburizing process it is quite common to simply quench directly from the carburizing, but this is not a requirement. The carburizing & heat treting can be done in seperate operations, though this would require bringing the part up to heat twice.

I totally agree with Chuck here, there simply is not a sharply defined "Line" to which the carbon penetrated & stopped but as he said it simply thins & eventually fades out as you go deeper from the surface. When the carbon content drops too low even though it may still be more than the original alloy as in the center it no longer hardens from the quench.

I believe this is basically what Dick was saying, but his statement seemed to indicate that casehardening was not heat treating, which it of course is.

Rocketman/DDA. I do not agree that the depth of hardness would be .002" A typical figure would be .008" per hour at carburising temperature.Gun actions are held for 1&1/2 - 2 hours so an effective case depth of .012"-.016 would be anticipated.

Thank you, gents, a very good discussion.

Chuck, can you go a bit deeper into the circumstances of seeing gradiant carbon content to the depths you indicated? Gun parts? I don't disagree, but would like to know more. I certainly agree 100%with the gradiant concept, but am surprised at the 0.050" number. 2-p, any input on depths likely for guns? I've heard of depths to 0.150", but only under very special circumstances.

DDA

I have in my shop a Greener FH35 that appears to have escaped the hardening process entirely. Either that or every part of it was annealed and left soft. The gun has obviously given years of good service and is still mechanically sound. Unfortunately all the engraved surfaces are worn down to the point of being barely discern able. Action, fore end iron, trigger plate top lever Deeley latch, trigger guard. It seems none the worse for wear but this seems to reinforce the argument that Hardening was more to protect the aesthetics rather than contribute strength.

Any budding engravers need a project??

My sentiments exactly and we're still springing along....

I have in my shop a Greener FH35 that appears to have escaped the hardening process entirely. Either that or every part of it was annealed and left soft. The gun has obviously given years of good service and is still mechanically sound. Unfortunately all the engraved surfaces are worn down to the point of being barely discern able. Action, fore end iron, trigger plate top lever Deeley latch, trigger guard. It seems none the worse for wear but this seems to reinforce the argument that Hardening was more to protect the aesthetics rather than contribute strength.

Any budding engravers need a project??

My sentiments exactly and we're still springing along....

A friend has a Birmingham 16 gauge singleshot hammergun. It was loose when he bought it. He sent it to a gunsmith both he and I consider to be very good. The gunsmith tightened it. My friend took it hunting and fired a few shots. It was loose again. Back to the gunsmith, gunsmith fixed it, back to my friend, no charge. Again my friend shot it a few times and it went loose. Back to the gunsmith. After investigation the gunsmith said that the frame was soft and had been improperly heat treated (after it left the maker) or had never been case hardened and wanted to have it case hardened so it would be springy. My friend, tighter than the proverbial bark-on-a-tree, declined and after the last tightening quit shooting it.

Best,

Mike

Everyone has some different view and experience with CCH. I feel like we have a tendency to mystify this process in gun circles because of the visual aspects of what it provides rather than the mechanical properties it provides.

Everyone should try to level set with some form of reference that is a good baseline and then take individual information as necessary to further your understanding.

The key here is that first and foremost case hardening is a heat treatment process for low carbon steels. First understand how they did it then and now.

From there you can work out how to translate the extra effort to get to CCH, which just adds the colors.

Get a baseline from some place like Wikipedia or buy a book on the heat treatment of metals.

http://en.wikipedia.org/wiki/Case_hardeningThen add to it:

http://www.doublegunshop.com/doublegunjournal_v7i4_9.htmhttp://www.keytometals.com/page.aspx?ID=CheckArticle&site=kts&NM=113I love these forums but in all the posts it can sometimes be hard to put all the different parts provided by different knowledgeable folks into the right order to fully see the puzzle you are trying to build and solve. Take a step back and find a reference that allows you to level set so when reading all the good posts you can put them into the right order.

Jason

....The gunsmith tightened it. My friend took it hunting and fired a few shots. It was loose again. Back to the gunsmith, gunsmith fixed it, back to my friend, no charge. Again my friend shot it a few times and it went loose. Back to the gunsmith. After investigation the gunsmith said that the frame was soft...

I thought putting a loose action 'back on face' did not involve any adjustment to the frame. Was the smith saying that each shot was bending the frame, but all was good with the pin, face of the barrels, etc. I wonder if it was just a pain in the tail gun, that was getting into more time than the job was worth.

The smith was welding the hook and then fitting it. Then after a few shots it would go loose again. Finally figured out the frame was bending (not flexing).

My post was unclear. Thanks Craig!

Best,

Mike

Don,

The casehardening I had these experiences with were not guns, but they were casehardened articles in the nuclear/aerospace biz. I was a toolroom machinist modifying these parts. I don't know exactly what process by which they received their casehardening. It could have been any of the "casehardening" processes to a low carbon steel.

I've milled and turned such parts over the years. The basic approach was always to take a deep enough initial cut to get under the hardened layer. What resulted in all circumstances was the typical dull milled/turned finish of the softer metal and a transition to a shiney-er (technical term) surface finish in the harder areas. It's common for machinists to get a "feel" for how hard metals are when they machine them. This comes from not only how hard they percieve the cutter and machine are working, but also what the finish of the metal looks like. Harder steels leave a much finer finsh. The harder the steel is, the finer the machined finish. Conversely, soft steel leaves a dull and sometimes rough finish (depending on grain size). Maybe Miller can cite some of his experiences as well.

The smith was welding the hook and then fitting it. Then after a few shots it would go loose again. Finally figured out the frame was bending (no flexing).

My post was unclear. Thanks Craig!

Best,

Mike

Sounds like too hot of a load to me.

Let me be explicit, case hardening and heat treating are two fundamentally different processes.

One relies on a temperature/time profile to increase the bulk tensile strength of a material and the other reiles on the diffusion of carbon into the surface of a material to increase the surface hardness. The only commonality is heat.

http://en.wikipedia.org/wiki/Case_hardening-Dick

Where's Ed's torch fit in ?

Dick,

Sorry that my post was confusing. Heat treatment is a general term that can describe color case hardening or through hardening. Both use heat to treat metal.

The better terms to use when describing the two types of metal treatment you are referring to are color case hardening and through hardening.

As my previous post suggests, working to level set first and take all these different observations is a must when discussing something this technical in nature.

Jason

http://www.precisionheattreat.com/difference.htmlThe most common question about heat treating

What is the difference between case hardening and through hardening?

The most common metal is steel which is available in many different alloys. The most common type of steels are:

1: Those which may be grouped under the heading "mild steel" and generally contain less than 0.25% carbon.

2: Those classed as medium to high carbon which contain carbon over 0.25%.

medium carb. 0.25% - 0.5%

high carb. 0.5% - l.0%

The through hardening process is used on medium and high carbon steels. Case hardening is used on mild steels.

Hardening occurs during heat treating when the steel (containing sufficient carbon) is cooled rapidly (quenched) from above its critical temperature. This temperature varies for different alloys but generally is in the range 1500oF- 1900oF.

A mild steel treated in this manner would show no appreciable increase in hardness. In order to make this steel react its carbon content must be increased. In the case hardening process the surface layer of the mild steel has its carbon content increased by a prolonged contact at a high temperature with a chemically reactive source of carbon. If this steel is subsequently quenched it will harden the surface layer, also known as the case, -hence "case hardening". The case depth will generally be from two thousandths of an inch up to one hundred and fifty thousandths of an inch. However the most common depth is in the range .020" - .030".

lt is important to choose the correct steel and the appropriate process to achieve the desired end result. For moderate strength with moderate surface hardness choose a medium carbon steel - through hardened.

For a very hard surface where a lower core strength is acceptable choose a low carbon steel - case hardened.

MILD STEEL CANNOT BE THROUGH HARDENED

MED. & HIGH CARBON STEEL CANNOT BE CASE HARDENED

(although other surface treatments are available)

The process which adds the carbon to the surface of low carbon steel is "Carburizing". This carburizing process itself does not add hardness other than the small amount of higher carbon steel over low carbon steel. The subsequet quench from an elevated temperature produces the hardness just as it does in a higher alloy through hardening steel. The carburized low carbon steel will harden only to the extent its carbon has been raised high enough to be effected by the ""Heat Treatment". Steels with a higher carbon allooy do not need (in fact is is normally not desirable) the carburizing step, but the heating & quenching part is essentially the same heat treatment as given to the other. Exact alloy content determines the quench medium & thus we have water hardening, oil hardening & air hardening steels.

The hard outer surface over a soft core has led to the term "Case Hardened" being a generally accepted term, but technically it is carburized & hardened, the hardening being done by heat treating. As previously stated it is most often combined into a single operation. Never-the-less the heating & quenching is nothing but plain old heat treating.

When carburizing & hardening parts in the machine shops I worked in we always drew the hardening to a temp of around 300°-350°F after being quenched. This left the surface at virtually maximum hardness but was done to prevent surface checking of the surface. I saw one piece on which this step was omitted & the following day its surface was full of small cracks. I do not recall ever seeing this mentioned in relation to CCH of gun frames & have often wondered why.

Even on a through hardening alloy steel if it has much thickness there will be some gradient to the hardness, as the center simply cannot cool as fast as the surface, resulting in some loss of hardness to the core, though certainly not to the same extent as a case hardened part.

As a general rule parts carburized by the molten

Cyanide process do not acheive as deep penertration of the carbon as those carburiced by the charcoal "Pack" process. I have never worked where the Cyanide process was in use, but used numerous which had been so treated.

now the plot thickens. let us say the poster's fox receiver is made of the post 1912 chrome-vanadium-nickel alloy steel that fox called chromox. how does he or anyone else who annealed it, get it reheattreated by quenching? forget about the case hardening. temp and time parameters? what is the rockwell target? have any of you men who had fox receivers redone by noted restorers, ever been told how hard your receiver is on the standing breeches, water table etc?

let us say the poster's fox receiver is made of the post 1912 chrome-vanadium-nickel alloy steel that fox called chromox.

Fox used Chromox steel (marketing name) on the barrels NOT the receiver forgings.......

Fox used Chromox steel (marketing name) on the barrels NOT the receiver forgings.......

pa24, you're wrong on that. beginning with intro in 1912, 16 and 20 bore receivers were mostly chromox with a few carbon steel here and there. also, carbon steel for 12 gauge receivers was phased out after 1912 and within a few years they all were made of chromox too.

first poster with the question was bbman. what say the site experts? what's he supposed to do now if his annealed receiver is chromox steel but with unknown % of alloying elements?

I have owned a good many Foxes over the years and some have Chromox frames as they turn a bright nickel finish when case colors wear off.A good many have or had a duller gray finish and hardly if any shine.Have no idea what type steel they are.A Chromox frame has brighter case colors in my opinion.I have no idea which is best. I plan to have no engraving at all on the frame,even filed off Sterlingworth.Maybe i ought to leave it as is and not have frame hardened.It should be easy to bend frame back if it does get off face? Thanks for all the response. Bobby

Do any of the Fox records correlate serial # with action alloy? Do Fox records indicate the exact alloy of "chromox"? Do Fox records indicate the heat treat processes used?

Why would Fox use "chromox" for actions? Barrels are not heat treated. So, why use a heat treat alloy for unheat treated barrels? Or, did they use "chromox" for actions exactly because it didn't need a heat treat?

I don't know what "Chromox" is but I suspect it's an early chromoly steel.

On the frames wearing to a bright "nickel" finish as an indicator of the alloy being chromox, it brings to mind LC Smiths. All LC smiths I've had wore to a bright nickel like finish, but all were case hardened low carbon steel as well.

Let me be explicit, case hardening and heat treating are two fundamentally different processes.

....the other reiles on the diffusion of carbon into the surface of a material to increase the surface hardness....

I believe if you case harden, harden being important, you had to do the exact same fundamental metallurgical process. Carbon alone in iron will not harden unless its arranged as martensite. I don't believe its possible to 'case harden' and 'heat treat' as two separate procedures on the same low carbon receiver using charcoal pack and water quench.

I suppose heat treatment is generally thought of as hardening, but I guess steel might be treated with heat for results other than hardening. I'm still not sure though what process or goal of 'heat treating' the core of a low carbon steel receiver would be.

fox advertised chromox as chrome nickel vanadium alloy steel but i've never seen the percentages quoted. those who own fox guns should be proud to know fox was way ahead of competing makers in using alloy steel starting 1912 with the 16 and 20 gauge guns. that was years before winchester did the same with its m21. those interested in the winchester's comparison of its alloy steel, properly heat treated, and the same steel case hardened, should refer to that testing in schwand's 21 book. suffice to say the heat treated alloy was way stronger than the same steel, case hardened. now back to bbman's dilemna. he probably has a chromox small gauge receiver, what's he to do now that its annealed? what say our resident metallurgists and mech e's?

Nitro,

Since the Fox continued to be casehardened, even thru the Savage years, I suspect the alloyed steel you describe for the frames did not contain high carbon content and therefore continued to be casehardened.

Note that "Steel" is itself an alloy of iron & carbon. What we normally refer to as "Alloy Steels" means they have some other alloying component than carbon. Most, but not all, alloy steels have a high enough carbon content to allow through hardening. There are some low carbon alloy steels produced specifically for case hardening purposes. As the fox Chromox frames were "Case Hardened" as I understnd it I can only assume they were of too low a carbon content for through hardening, The M21's frame was a higher carbon frame suitable for through hardening. Thus while both are "Alloy Steels" they are not identical in terms of treatment. As to strength if one looks at the charts of various steels giving their strengths they will be hard put to find a heatreated alloy steel which is not stronger than a case hardened mild steel. That said though when the requirements are met with an adequate safety margin, there is little "Real Gain" acheived from a practical standpoint.

As to terminology "Heat Treat" is not a specific process. The hardening portion of case hardening is to quench from a temp above critical temp, same as on through hardening steels. While true the hardening cannot be accomplished seperate from "Heat Treating" the carburizing process can, & sometimes is, done as a seperate operation. In this process the part is brought up to heat & held for the required time in the carbon rich atmosphere & then allowed to cool slowly. The Carbon Case is thus acheived, but it is not hardened. Following this the part is then "Heat Treted" IE brought up to temp & quenched. Unles there is some specific need to do so both operations are ordinarily combined, IE the part is quenched directly from the carburizing step, even so it is basically a two-step operation. It differs from the heat treating process of a through hardening steel only in the first or carburizing step.

fox advertised chromox as chrome nickel vanadium alloy steel but i've never seen the percentages quoted. those who own fox guns should be proud to know fox was way ahead of competing makers in using alloy steel starting 1912 with the 16 and 20 gauge guns. that was years before winchester did the same with its m21. those interested in the winchester's comparison of its alloy steel, properly heat treated, and the same steel case hardened, should refer to that testing in schwand's 21 book. suffice to say the heat treated alloy was way stronger than the same steel, case hardened. now back to bbman's dilemna. he probably has a chromox small gauge receiver, what's he to do now that its annealed? what say our resident metallurgists and mech e's?

Ned Schwing's book on the Model 21 and his discussion of the steel used in Model 21 frame manufactrugin has nothing to do with Fox shotguns. The Chromox and Krupp steels referred to in Fox manufacturing were for the barrels and not the frame. Winchester specifciations for the Model 21 and Fox specifications have nothing to do with each other.

Fox recievers continued to be of mild steel and required case hardening while Winchster recievers were manufactured of high tensile steel requiring no surface (case) hardening which resulted in Winchester recievers being blued and Fox case hardened.

I could not find my copy of McIntosh's bok on the Fox but I don't remember ever having read documented results for receiver steel used.-Dick

“Vanadium itself, when combined with steel very low in carbon, is not so noticeably beneficial as in the same carbon steel higher in manganese, but if a small quantity of chromiumis added, then the vanadium has a very marked effect in increasing the impact strength of the alloy.....Chrome-vanadium steels also are highly favored for case hardening. When used under alternating stresses it appears to have superior

endurance.”

Have a nice day

Mike

Based on differing research I would bet that the chrome/nickel/vandium steels used in the early 1900's were still low carbon content steels. Typically less than .3% carbon which still allows for case hardening, but likely increases the strength of the internal soft metal due to added alloying elements.

It would have been better to have the frame annealed prior to engraving and then case hardened. That would have been my recommendation.

Annealing resets the grain structure across the entire part during the cool down process. You don't get that during the heating phase of case hardening. So case hardening a second time without annealing may have a higher tendency to fail.

Here is another link to some general information on Chromium steels (41xx class) noting that there is 4118, 4120 and 4130 which can be case hardened. See description at bottom.

http://en.wikipedia.org/wiki/41xx_steelFrom one website noting chromium being added to low carbon steels:

The development of 9–12% chromium steels is reported to have originated in 1912 with the manufacture of a 12% Cr 2–5% Mo steel for steam turbine blades by Krupp and Mannesmann in Germany. However, in 1912–13 Brearley in the U.K., while attempting to develop high-temperature steels for gun barrels, accidentally discovered that martensitic steels containing 13% Cr and 0.2% C did not rust; the stainless characteristics of high-chromium steels were also recognized by Haynes in the USA and by Strauss and Maurer in Germany at about the same time.

I have no doubt that the gun mfrs were playing with steel alloys in the first half of the century and earlier. I think they're still tinkering around with alloys.

As to whether or not "chromox" had carbon of sufficient quantity to harden, I suspect it did. I also suspect the "chromox" barrel steel wasn't used for frames. I welded LC Smith barrels from the 20's era and found that they hardened at the weld HAZ and weld bead from the 'self-quench' even though I used a mild steel rod.

Don,

Here's a link to a site that has some data on casehardened 8620. 8620 seems to have a big following for custom makers of singleshot rifles and possibly custom doubles that will get casehardened. Of particular interest to you may be the notation about the carburized casehardened thickness. They are quoting 1.9 mm.

"I suppose heat treatment is generally thought of as hardening, but I guess steel might be treated with heat for results other than hardening.

craigd, heat can also be used to anneal (soften until re-heat treated) heat treated steel alloys.

"I'm still not sure though what process or goal of 'heat treating' the core of a low carbon steel receiver would be."

There would be no purpose of heating the core of a low carbon receiver. It is "along for the ride" when the receiver is being carburized and hardened.

Thanks, Chuck. I'll have a look at these. I agree with you that Chromox probably was a low carbon steel alloy. Thus, it would have worked fine for barrels which were heated sufficiently for tinning in the ribs and ?brazing? for joining and the lumps (I don't remember Fox barrels as being chopper lumps - could be wrong about that one). I also agree that it would have added some strength to the action, whether cased or not.

DDA

Ned Schwing's book on the Model 21 and his discussion of the steel used in Model 21 frame manufacturing has nothing to do with Fox shotguns. The Chromox and Krupp steels referred to in Fox manufacturing were for the barrels and not the frame. Winchester specifciations for the Model 21 and Fox specifications have nothing to do with each other.

Fox recievers continued to be of mild steel and required case hardening while Winchster recievers were manufactured of high tensile steel requiring no surface (case) hardening which resulted in Winchester recievers being blued and Fox case hardened.

Dick

You are correct Dick.

I also suspect the "chromox" barrel steel wasn't used for frames.

You are also correct Chuck.

Dick lays it out quite

matter-of-factly and is entirely correct.

ALL of the Fox frames were cyanide cased (after about 1910 or so) and were cased by Fred Heinzelman & Sons in Carlstadt, N.J. for as long as Fox was in business.......Heinzelman & Sons is still in business today and is still doing guns (110 years or so) and could probably answer all your Fox receiver frame alloy questions for the data compilers here who are interested.

Cheers,

Doug,

Although I think the chromox barrel steel wasn't used for frames, it is very possible that the differences that our members have seen in the frame characteristics was a result of other alloying agents being added or changed during production years. My guess is that nickel was probably added along the way and gave that yellowish shiney look that was mentioned.

Chuck, I would agree with that thinking, although the cyanide colors from Heinzelman stayed quite consistent over the years which would indicate the alloy mix stayed pretty much the same for a long time........if anyone here wants a complete analysis, they should forward a sample of their steel to Kachina Metal Testing Laboratories in Phoenix.

Kachina will conclusively analyze the steel for anyone that wants to know, in as much detail as you are willing to pay for......their primary business is aircraft steel and alloys. Kachina is an established metal laboratory with years of experience and all the latest equipment.

I have used them many times over the years and the results were outstanding.

In one machine shop in which I put in betweeen 11 & 12 years 4130 & 4340 were our two main alloy steels. I would likely be utterly amazed if I had some way of knowing just how many pounds of each of these alloys I machined on & virtually all of it was subsequently heat treated. In all that time I never saw a part made of either case hardened. We normally did not case harden a part having a carbon content higher than 0.2%. 4130 we considered a water hardening steel & 4340 an oil hardening steel. Both of these alloys we heated in a neutral salt bath to hold down surface oxidation. Although we did not use near as much of it, we did occasionally use 4140 which due to the extra carbon over the 4130 was also oil quenched.

An interesting note on this website

http://www.suppliersonline.com/propertypages/8620.asp is that it indicates that 8620 will have a core strength of 135ksi after carburizing,quenching, and tempering at 250-300F. 135ksi core is pretty dang good for a casehardened part.

My understanding is that at least a couple of the well known CCH outfits will accept 4140 to CCH. It doesn't apply to classic receivers, but they manage the process on an alloy that can deep harden.

I noticed the 1.9mm depth of case for 8620 was at much higher temp. and much longer duration than typical reports for gun part CCH. So chances are the significant sounding depth does not actually happen if 8620 is used in one of those repro. single shot receivers.

Both Turnbull and Bachelder will color harden a Parker Repro. I'm not sure what a Parker Repro is made from. I do have an open question over in the Parker Repro forum. But I suspect it's a 4140 frame.

I recall asking Oscar Gaddy about color hardening a 4140 gun and he suggested that Turnbull has successfully implemented a process for that.

Now, think of the action as the spring. Many times over the amount of metal in the core as in the case shell!! Post if you don't follow that logic or disagree.

Suppose we have a beam supported at each end and a heavy load midway. As that load was placed on the beam and the beam deflected the bottom of the beam would be placed into tension and the top of the beam into compression. If one were to graph the tension and compression in a cross section of that beam from top to bottom there would be a point where it is in neither tension nor compression. That point is only in shear. So that zero tension point contributes very little to the yield strength of the beam. And as you go to the top or bottom of the beam the compression and tension go up until they reach the top or the bottom. If the beam were an I beam the flanges on the I beam add strength exactly where the most tension and the most compression occur in the beam. The beam will take more load (pounds) before it yields (permanently bends) compared to another beam that was the same height and cross sectional area but with a rectangular cross section. And I vaguely remember that the distance from the flange to that point in the beam which is neither in tension nor compression is a major component of designing a beam.

And in a receiver the case hardened outer metal increases the the total yield point of the receiver. Pounds per square inch tension is not the only factor, it is how far that tension is from the zero stress point of the beam.

And the closer to that zero tension point in the beam the less the strain (stretching or compression) and the further that point is from it's yield point. And the less that point contributes to the resistance of the load because of the spring rate.

So it is not a simple case of calculating the percentage of the cross sectional area that is case hardened and pro-rating it's increased yield strength into the total strength of the action.

Thanks,

Mike

"And in a receiver the case hardened outer metal increases the the total yield point of the receiver. Pounds per square inch tension is not the only factor, it is how far that tension is from the zero stress point of the beam."

Case hardening has nothing to due with 'yield point' if your are referring to the point where steel in tension trasisitions from elastic to plastic deformation. Case hardening affects the hardness of the surface and the values are not additive.

"So it is not a simple case of calculating the percentage of the cross sectional area that is case hardened and pro-rating it's increased yield strength into the total strength of the action."

I have never heard of a calculation like that?

Both Hardness and Yield Strength are measures quantities and are not calculated nor is there any quantity defined as "total strength".

-Dick

It could be argued that gun barrels resist the most forces on firing. I also suspect that classic low carbon receivers were intended to fail slowly, generally bend instead of reaching a sudden fracture point.

If we are just talking about the effects of casehardening or through hardening on a given double gun frame, no matter how high the hardness of the frame is raised, it won't change the amount of deflection of the frame when fired at all.

The stiffness of a gun frame will not change from hardness nor changing the steel from mild steel to chromoly, hard or soft.

The stiffness of steel is pretty much the same thru all the alloys and unchanged by hardness.

It could be argued that gun barrels resist the most forces on firing. I also suspect that classic low carbon receivers were intended to fail slowly, generally bend instead of reaching a sudden fracture point.

Low carbon recivers were used because that was the extent of the Metalurgy at that time in history.

"Sudden fracture point is commonly known as Brittle Fracture and is a condition that a steel can be put into if not heat treated properly known as Martensite.

Recievers were annealed to remove the Martensite structure.

Iron along with its alloying elements form the many phases that steel can go through due to its manufacturing. These are referred to as Phase Diagrams.-

http://web.utk.edu/~prack/MSE%20300/FeC.pdf

The following is a good treatise. Note the section about Martensite.

-Dick

http://web.utk.edu/~prack/MSE%20300/FeC.pdf

"The stiffness of steel is pretty much the same thru all the alloys and unchanged by hardness"

What is stiffness?

Never miind. Stiffness is a quantity used for a structure and not a material. Elasticity is the term used for a material. I suppose one could measure the stiffness of a reciever but I have not heard of it being done.-Dick

"Case hardening has nothing to due with 'yield point' if your are referring to the point where steel in tension trasisitions from elastic to plastic deformation."

Case hardening increases the yield point of the case hardened metal.

My Marks "Standard Handbook for Mechanical Engineers" is at the office but it states that case hardening increases the yield point, which is the point (stress) at which steel plastically deforms and gives examples of different results for different case hardening specifications.

"I have never heard of a calculation like that?"

Dick if you will look at the sentence I quoted from Rocketman I was trying to counter his point about the relatively small cross sectional area of the case hardened metal compared to the total cross-sectional area in regard to the plastic bending of the action. I think Rocket was arguing that the small percentage of the case hardened steel is not enough to change the plastic bending point of the receiver. I wasn't arguing for the math model but against it.

Thanks for the comments. I have learned much on this thread.

Mike

Edit: "My Marks "Standard Handbook for Mechanical Engineers" is at the office but it states that case hardening increases the yield point, which is the point (stress) at which steel plastically deforms and gives examples of different results for different case hardening specifications." is incorrect. It does not say what I wrote in this post.

"What is stiffness?" Spring rates are a measure of stiffness, pounds/inch, foot-pounds/degree etc...

I will find a copy of Marks.

-Dick

If we are just talking about the effects of casehardening or through hardening on a given double gun frame, no matter how high the hardness of the frame is raised, it won't change the amount of deflection of the frame when fired at all.

The stiffness of a gun frame will not change from hardness nor changing the steel from mild steel to chromoly, hard or soft.

The stiffness of steel is pretty much the same thru all the alloys and unchanged by hardness.

But by increasing the yield point of the steel the frame can take more displacement without plastic bending. And since spring rates go up with some power(d squared or d to the power of 1.5 etc...) of displacement and a higher yield point receiver can take more displacement it's spring rate is higher right before plastic failure that a "soft" frame.

This has been an interesting thread! Fertile grounds for a book on the metal types and treatments for double guns old and new by as many makers as possible. Would take someone far more savy than I!

Low carbon recivers were used because that was the extent of the Metalurgy at that time in history.

"Sudden fracture point is commonly known as Brittle Fracture and is a condition that a steel can be put into if not heat treated properly known as Martensite.

Recievers were annealed to remove the Martensite structure..

I believe, historically, medium and high carbon steel was well known and available in the late 1800's early 1900's. I think even today there's the use of medium carbon steels, but I believe there's a reason why high carbon steels are generally not used in receivers and barrels.

I don't believe martensite is a heat treating problem. I think the whole point to the thread is the importance of case hardening, or the formation of martensite on the surface of steel that is unable to harden on its own. The thread is also asking if the hardness, martensite, were removed by annealing if the gun were ok to shoot. So, there seems to be an implication that we don't want to anneal the hard case of a receiver for possibly safety or durability reasons.

Dick,

I'll defer to your explanation of MOE. Clearly, some of the folks here confuse MOE, ultimate tensile strength, and yield strength. I suppose a stress/strain diagram of two coupons, one hard, one soft would be helpful.

....no matter how high the hardness of the frame is raised, it won't change the amount of deflection of the frame when fired at all...

Hi Chuck, this was the exact point I was awkwardly trying to make earlier.

Would you be able to comment, and I'm interested to learn, if all is equal, will the hardened sample be able to deflect by a greater amount, before becoming inelastic, than the softer sample. I'm not thinking of force required as the samples approach their yield, but distance of deflection before first signs of permanent deformation.

Again, purely to learn, don't mean to flog around on the ole dead horse.

I will find a copy of Marks.

-Dick

Dick it was actually by two authors. The other one was something like Baumeister. I bought it new in 1978.

Thanks,

Mike

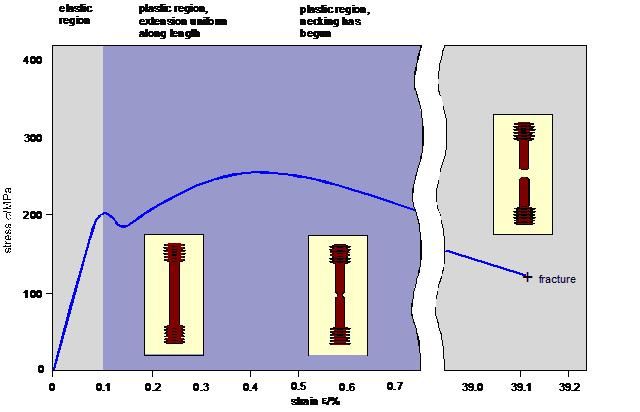

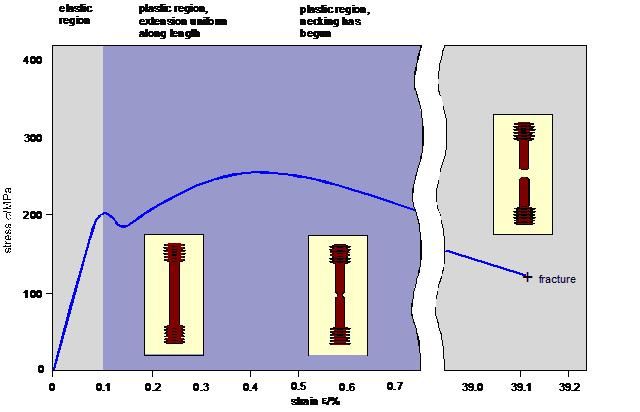

This first stress-strain diagram show mild steel.

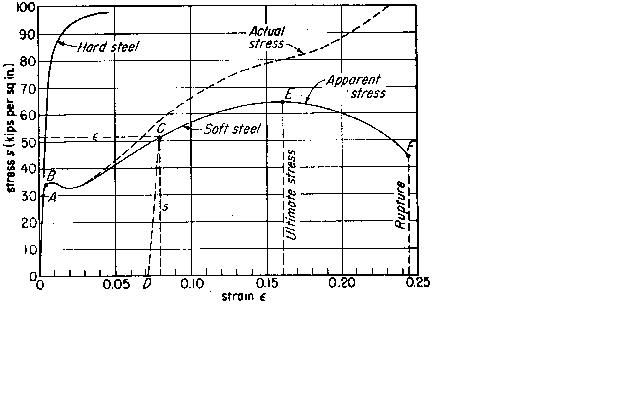

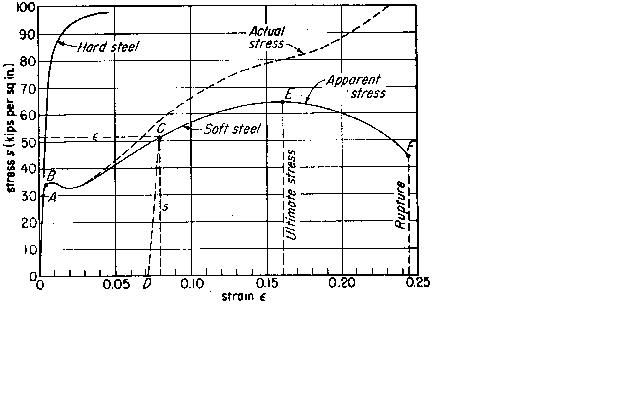

This second diagram shows a hardened steel curve and a soft steel curve on the same diagram. You can see the stress and strain track exactly on top of each other (extreme left side of the diagram) until the soft steel starts to yield. The hard steel curve continues upward and you can see that it doesn't have much plastic region (more brittle). This is what you'd see in two identical flat springs, one soft and the other heat treated.

I will find a copy of Marks.

-Dick

Dick it was actually by two authors. The other one was something like Baumeister. I bought it new in 1978.

Thanks,

Mike

Dick when Chuck deferred to your expertise I got worried. I drove to my office. I am at my office looking at the "Standard Handbook for Mechanical Engineers". It doesn't say what I said it says.

If I understand what I read this article says that carbo-nitriding low carbon steel raises signifigantly raises it's yield strength and tensile strength. I know we are talking about case hardening by carburizing

http://resources.metapress.com/pdf-preview.axd?code=j5m0rm7q16833674&size=largestBest,

Mike

A Mike, I'm really impressed with your research and consideration of beam mechanics - good work. However, on with the discussion.

"But by increasing the yield point of the steel the frame can take more displacement without plastic bending."

Remember, only the CH steel case has a higher yield; the low carbon steel part is unchanged.

"And since spring rates go up with some power(d squared or d to the power of 1.5 etc...) of displacement and a higher yield point receiver can take more displacement it's spring rate is higher right before plastic failure that a "soft" frame.

No, spring rate is a force per displacement number. A "hard" spring will have more spring force than an equal soft spring, but only after the "soft" spring has yielded and the "hard" spring has not and continues to deflect without yielding. The two will have essentially the same spring rate if of equal dimensions. Spring rate must not be confused with spring force; spring force is spring rate times deflection.

In the case of the action/frame, it does, indeed, act like a beam with a strain gradient across it. However, the bulk of the stress will still be carried by the far more massive "soft" core. The case will add only "steel" strength to resist bending. The fact that the case is "hard" will add nothing extra until after the core has yielded. In a yielded frame, the "soft" core will resist returning to original dimensions and the "hard" case will attempt to force the "soft" core back. The "hard" case will be able to return the "soft" core part way back. It would take a very thick case to return it most of the way. As the yielded action moves toward original dimension, the yielded core would increase its resistance (spring force) and the spring force from the case would decrease. Once yielded, the case will not be able to overcome the core and return the action all the way to original dimensions.

Questions? Comments? Opposing views?

DDA

My head is harder than before I read all this.....

Gun talk get you excited jOe.

I will find a copy of Marks.

-Dick

Dick it was actually by two authors. The other one was something like Baumeister. I bought it new in 1978.

Thanks,

Mike

I perused Marks 10th Edition today at my library and looked at the sections on steel and on beams.

I could not find any discussion on calculating or measuring yield stress with a work hardened surface. If you can point me to a section, I will try to find it in a copy. Please include the edition and page number(s) as I am sure the UW Mechanical EngineeringDepartment will have copies archived.

In any event it is a moot point as I don't believe any of this information was available or used by the designers of the Fox shotgun at the turn of the century(1900) or so.

The original question concered whether it was safe to shoot a Fox with an annealed frame.

The correct answer would be yes because the steel was in a mild condition to start with and the lack of case hardening does nothing to the strength of the reciever.-Dick

Dick_dup1, this thread had gone on for 10 pages of obscure theory and stuff I didn't understand. Your posts have all seemed authoritative and clear. I too appreciate your last post, Thanks...Geo

Dick I bet you missed what I wrote later Saturday. From a few posts up the thread. I added an edit (in Red) to one post and added two more:

"Case hardening has nothing to due with 'yield point' if your are referring to the point where steel in tension trasisitions from elastic to plastic deformation."

Case hardening increases the yield point of the case hardened metal.

My Marks "Standard Handbook for Mechanical Engineers" is at the office but it states that case hardening increases the yield point, which is the point (stress) at which steel plastically deforms and gives examples of different results for different case hardening specifications.

"I have never heard of a calculation like that?"

Dick if you will look at the sentence I quoted from Rocketman I was trying to counter his point about the relatively small cross sectional area of the case hardened metal compared to the total cross-sectional area in regard to the plastic bending of the action. I think Rocket was arguing that the small percentage of the case hardened steel is not enough to change the plastic bending point of the receiver. I wasn't arguing for the math model but against it.

Thanks for the comments. I have learned much on this thread.

Mike

Edit: "My Marks "Standard Handbook for Mechanical Engineers" is at the office but it states that case hardening increases the yield point, which is the point (stress) at which steel plastically deforms and gives examples of different results for different case hardening specifications." is incorrect. It does not say what I wrote in this post.

I will find a copy of Marks.

-Dick

Dick it was actually by two authors. The other one was something like Baumeister. I bought it new in 1978.

Thanks,

Mike

Dick when Chuck deferred to your expertise I got worried. I drove to my office. I am at my office looking at the "Standard Handbook for Mechanical Engineers". It doesn't say what I said it says.

Don thanks for the kind words.

A spring's spring rate goes up with the displacement. At 2" displacement the spring rate might 100lb/in. at 3" displacement the spring rate might be 500 lbs/in. So my contention that the receiver gets stiffer (spring rate goes up) as the receiver is flexed more is correct.

In the beam example the displacement (stretching) at the bottom of the beam is twice as much at the surface as it is half-way between the surface and the line that is neither in compression or tension.

And since the surface has had the yield point raised by case hardening the surface can stretch more before it yields and goes into plastic deformation. And since the point half way between the surface and the zero tension line is only stretching half as much as the surface it doesn't stretch enough to reach it's yield point even though it's yield point is lower.

And since the maximum deformation is at the surface and since the spring rate of the metal in the surface goes up as it deforms (like a spring has a higher spring rate at 3" displacement than it does at 1") the bulk of the load is carried by the exterior of the frame.

Don I repeat, it is not a simple matter of calculating the percentage of the cross section that has been case hardened and then pro-rating that increased yield strength into the strength of the frame. The exterior of the frame carries more because it has %deformed more and so is in higher tension than the interior. The interior point at the zero tension line is not providing any resistance at all because it is, by definition, at zero tension.

So case hardening a frame increases it's ability to resist plastic deformation.

I agree with Mikee. It's not a simple binary answer. Casehardening goes much deeper than would be portrayed by the numbers. The resultin effect is more htan "notheing".

The simple binary answer was back on page one.

I found data on 8620 stating it will have the core strength raised during casehardening. The data showed a 135ksi core after casehardening.

Arrrgh, my connection cyber ate some terrific nonsense I typed out.

In a nutshell, your reference for 8620 back on page 7 showed most performance measurements were 'typical for steel'. With the ability to look up carbon migration, can 8620 in charcoal, at maybe 1400* for maybe an hour or two, be carburized any deeper than say ten thousandths.

I think there's a reason and affect for gun CCH, but the process would not seem to be able to increase core strength. It's still the same 8620 on the inside. Industrial applications such as ball bearings or gears may be an entirely different situation with the significantly higher temperatures, much longer times and optimized environment.

I also suspect that the performance of a spring, receiver, would have a lot to do with the design. I think very little on a receiver does not act like a spring when a shell is fired. There seems to be an implication creeping in that thin case annealing will automatically cause permanent deformation of the part. It just doesn't seem to make sense if the forces of firing a shell does not exceed the material or design.

Craig,

Just talking about 8620 for a moment, since that is a popular choice among the custom singleshot rifle makers. 8620 has a normalized strength of about 90ksi and that data I referred to earlier states that casehardening will bring the core up to 135ksi. That says that 8620 is core hardening from the low teens in the RC scale up to the high 20's. If true, that would make for a great combination of core and surface hardness for a gun.

The problem with the beam analogy is strain compatibility. The surface layer and core layer need to strain in proportion to their depth within the beam section. But, the gradient from hard case and soft core is supposed to be quite sharp. The cased surface cannot achieve the strain value necessary to get to its higher yield stress without the core yielding first.

I don’t know if a gun frame is like a beam or what results may come from shooting the annealed Fox but, I suspect Dick is right. Case hardening the surface of a steel element should not make it significantly stronger.

Don thanks for the kind words. Well deserved, you are doing a very good job of keeping this discussion on debate points.

A spring's spring rate goes up with the displacement.

If so, please explain how a simple linear "milk" (spring) scale works.

At 2" displacement the spring rate might 100lb/in. at 3" displacement the spring rate might be 500 lbs/in.

Only if the spring is designed to be non-linear. Such springs can be made, but they require collapse of some element(s) of the spring.

So my contention that the receiver gets stiffer (spring rate goes up) as the receiver is flexed more is correct.

Only if the receiver acts as a non-linear spring. Since there would be no element to collapse, I seriously doubt that the receiver would be non-linear in bending.

In the beam example the displacement (stretching) at the bottom of the beam is twice as much at the surface as it is half-way between the surface and the line that is neither in compression or tension.

And since the surface has had the yield point raised by case hardening the surface can stretch more before it yields and goes into plastic deformation. And since the point half way between the surface and the zero tension line is only stretching half as much as the surface it doesn't stretch enough to reach it's yield point even though it's yield point is lower.

I understand you to be saying that the first point to yield would be the area immediately below the case layer; the first point where there is no heat hardening.

If so, I agree. However, this point/layer will yield before the case layer has sufficient deflection to add significant extra force. The layer/case of heat hardened steel (carbon penetration required) would have to be quite thick to add increased force resistance.

DDA

And since the maximum deformation is at the surface and since the spring rate of the metal in the surface goes up as it deforms (like a spring has a higher spring rate at 3" displacement than it does at 1") the bulk of the load is carried by the exterior of the frame.

Don I repeat, it is not a simple matter of calculating the percentage of the cross section that has been case hardened and then pro-rating that increased yield strength into the strength of the frame. The exterior of the frame carries more because it has %deformed more and so is in higher tension than the interior. The interior point at the zero tension line is not providing any resistance at all because it is, by definition, at zero tension.

So case hardening a frame increases it's ability to resist plastic deformation.

....That says that 8620 is core hardening from the low teens in the RC scale up to the high 20's. If true, that would make for a great combination of core and surface hardness for a gun.

Thanks Chuck. Those hardness numbers (rockwell c ?) are in a similar range of what 1018 might be. I believe 8620 will or can get a bit harder, but it may be down to the alloy. You're right, I bet the old time makers would give it a close look.