Would anyone want to share their process of nitre bluing external parts, like trigger guarda, screws, for end metal.

I'm guessing nitre bluing is the correct term.

I have a few parts guns that I would like to experiment on and would like to know the process and steps.

Thanks in advance.

Nitre Blue salts are readily available at most smith sources. The salts are boiled straight without the addition of any water in a steel tank to over 600 F, I use 625 F. Small steel tanks are available from Brownells for this purpose.

The cleaned and prepared parts, same cleaning as rust blue to 600 W/D, then they are acetoned, dried then dipped into the tank and shortly you have your nitre blue finish.....the lower you drop the temperature the lighter the color. I leave the parts in the tank usually about 10 minutes.

I hang the parts using a small roll of medical stainless steel wire that I have, surgical wire. Very small diameter and it will twist over almost any thread size or opening in the parts/screws etc.

Regards,

If you are looking to duplicate charcoal bluing colors then you will need to heat your salts more than 625F. If you are trying to get some form of temper color like fire blue then 625F will work just fine. To get charcoal blue color (blue-black) I have found that 730-750F works for most steels. On some modern steel parts I have had to increase the temp. It takes about 15 minutes to get the correct color. The parts need to be recently polished, degreased,and dried. When the parts first go in I gently agitate them until all of the bubbles are off the parts. When the desired color is reached I take the parts out, let them cool, rinse in water, and soak in oil. On some steels (like 2nd generation SAA cylinders) the parts need to be submerged several times.

I first learned to nitre blue from Oscar. He heated his salts to over 900F. I used to do this but found that the same charcoal blue color developes on most steels at a lower temperature. I have mixed my own salts from salt peter and used Brownells. Both salts give the same results. Oscar was concerned that Brownells salts could not be heated to the correct temperature without breaking down. I have heated Brownells salts to 900F with no problems.

Some steels are more difficult to blue. With a little practice you can duplicate the charcoal blue color found on pre-war II guns. I have blue about 15 Colt, 6 Winchester actions, 3 Marlin actions, and over 25 shotgun trigger guards using this method. I have compared the blue color obtained this way with original Colts in high condition. The colors are identical. I hope this helps.

Would anyone want to share their process of nitre bluing external parts, like trigger guarda, screws, for end metal.

I don't think David is going to be doing any Single Action Army Colt 'hard steel' Cylinders or Antique Winchester Frames, therefore 625-650 should be a good temperature for his trials on LC Smith parts. Softer steel LC Smith trigger guards and forend irons look real nice at these temps, as they were not 'bright charcoal blue' colored originally. The temperature is an easy variable that he can play with.

I recommend the Brownells Nitre Blue material.

Best,

I would try it but am afraid one sweat droplet would cause a major eruption! lIKE THE COLOR, THOUGH! Steve

Doug,

I'm glad that 625-650 works for you. I must be doing something different because at that temperature range I don' t get the correct blue-black color. I do get a very attractive dark blue at those temperatures. This dark blue looks very nice but doesn't exactly match the original blue- black color of my original vintage shotgun trigger guards. The color difference is less noticeable on guards polished at 400 grit or less. With my setup it takes at least 730F. This is just my experience. Thanks for sharing how you do it.

Shawn,

Thank you for your information and input.....Yes, every set up is a little different and the results vary accordingly.

Your CCH temps on the other post are identical to mine BTW. I am sure your results are really nice. Post some CCH pictures if you get a chance, thanks.

Best Regards,

First thing, thanks to those that answered. Doug is right, I will be trying only L.C. Smith parts. I did look up Brownells Nitre Blue and will get some soon.

I would like to do some trigger guards, and a few non-ejector for-ends. I have a few hammer guns that were "klunkers" and have been working to "fix" them up some and these would be good candidates.

Doug do you do any case hardening/coloring. I also have a few receivers and lock plates that could be done?

Doug do you do any case hardening/coloring. I also have a few receivers and lock plates that could be done?

Hi David:

Yes, I do a fair amount of CCH, but I am not taking on any more outside business at this time, but thank you for asking David.

Best Regards,

Potassium nitrate is nothing more than "stump remover" sold in 1 pound containers at the local home center ( Lowes, HomeDepot).

It's all I've ever used, gives a nice deep blue/black.

Niter BlueScroll down to the 5th post.

More Niter blueHTH, Robert

Highstrap, very interesting articles and thanks for posting them. I will try the stump remover if my Lowe's has it.

That's 329 degress c?! What the heck? I black all of my stuff at 143 deg c thats 289 f. which is the absolute perfect blacking temp. Maybe jts the salts you are using need a higher temp...I'm glad I'm using mine because trying to lower boiling points is a risky process the higher the temp...

T

143°C/289°F sure doesn't sound like "Niter" blue to me. This sounds like "Hot Salts" bluing to me as this is within the proper temp range for them.

Tony, glad you see that you are back and that everything went fine.

Yes, my bad, I miss-understood what was being discussed. JDW, thanks, I'm still in hospital but hoping to be released today or tomorrow.

Cheers

T

HIGHSTRAP, went to the local Lowe's today and found it. Spectraside (sp)made it. Comes in a 1 lb. bottle . Crystals are white in color. I bought a small steel loaf pan, and when I got home I asked the good woman if she had something to trade for it. She did and I will use that. I still need a thermometer. I know she has one for melting sugar, but I won't use it. I did see one that when to 700 degrees and that I will get.

Parts are polished, ready to go.

I finished the barrels, gave them 4 rustings, 3 boilings and 1 etch, could have done more, but that is good enough.

Nice barrels for an F gr. hammer gun

Oscar used to melt KNO3 and a dash of AL Sulfate in a pan and let the parts soak until the right color was reached. Be careful the right color is not multi color from just the heat.

bill

JD, What you need is a lead thermometer.I got mine here, goes to 1000 deg.

Thermometer The first time you heat the crystals a black material will rise to the surface, but as full temp. is reached all will blend together and become transparent.

Be sure to wear gloves and face protection. Anything that gets in the salts, like a drop of moisture or a bug, will cause the salts to spatter out of the pot! Be careful!

HTH, Robert

Robert, thanks for the link. I will try a place near me for one. I bookmarked yours and will get it if the other one is not high enough.

I do have a face shield and welding gloves, and actually weldng jacket for protection, and will keep the oil far enough away as to be safe.

Thanks, and will post some pictures when I start.

Bill, I have heard about using the Sulfate, but don't know where to get some. I have a few parts that aren't good, will polish them and do them first with just the stump remover.

The fumes are pretty bad, so make sure you have good ventilation.

The fumes are pretty bad, so make sure you have good ventilation.

Thanks, I will either do it outside or use a fan or both.

If you are looking to duplicate charcoal bluing colors then you will need to heat your salts more than 625F. If you are trying to get some form of temper color like fire blue then 625F will work just fine. To get charcoal blue color (blue-black) I have found that 730-750F works for most steels. On some modern steel parts I have had to increase the temp. It takes about 15 minutes to get the correct color. The parts need to be recently polished, degreased,and dried. When the parts first go in I gently agitate them until all of the bubbles are off the parts. When the desired color is reached I take the parts out, let them cool, rinse in water, and soak in oil. On some steels (like 2nd generation SAA cylinders) the parts need to be submerged several times.

I first learned to nitre blue from Oscar. He heated his salts to over 900F. I used to do this but found that the same charcoal blue color developes on most steels at a lower temperature. I have mixed my own salts from salt peter and used Brownells. Both salts give the same results. Oscar was concerned that Brownells salts could not be heated to the correct temperature without breaking down. I have heated Brownells salts to 900F with no problems.

Some steels are more difficult to blue. With a little practice you can duplicate the charcoal blue color found on pre-war II guns. I have blue about 15 Colt, 6 Winchester actions, 3 Marlin actions, and over 25 shotgun trigger guards using this method. I have compared the blue color obtained this way with original Colts in high condition. The colors are identical. I hope this helps.

I REALLY try to stay out of these topics but Shawn is the only one that has the correct process. In my experience 625 degrees will not get you to the next color phase or the correct color for niter blue. If you want those pretty temper blues go for it, if you want blue black then use Shawn's temps. I run my salts @ 800 degrees FWIW.

I also learned the process from Oscar. He showed me how the color process advanced into a secondary or final color. Apparently you need enough heat to get there.

I use pharmacy grade KNO3 plus a VERY small amount of Manganese Dioxide as an additional oxidizer. I really don't believe that the Manganese Dioxide is needed but I use it anyway because I have it. Probably the tree stump stuff will work just fine but I have no idea if there are any additional chemicals in the mix.

I've heard people say that niter blue is very thin and not very durable. That may be because they didn't have the thick oxide coat that comes with the second phase of blue. I can tell you that I left a trigger guard in to long and the niter blue actually started to flake off like you mave have seen on some Winchester frames.

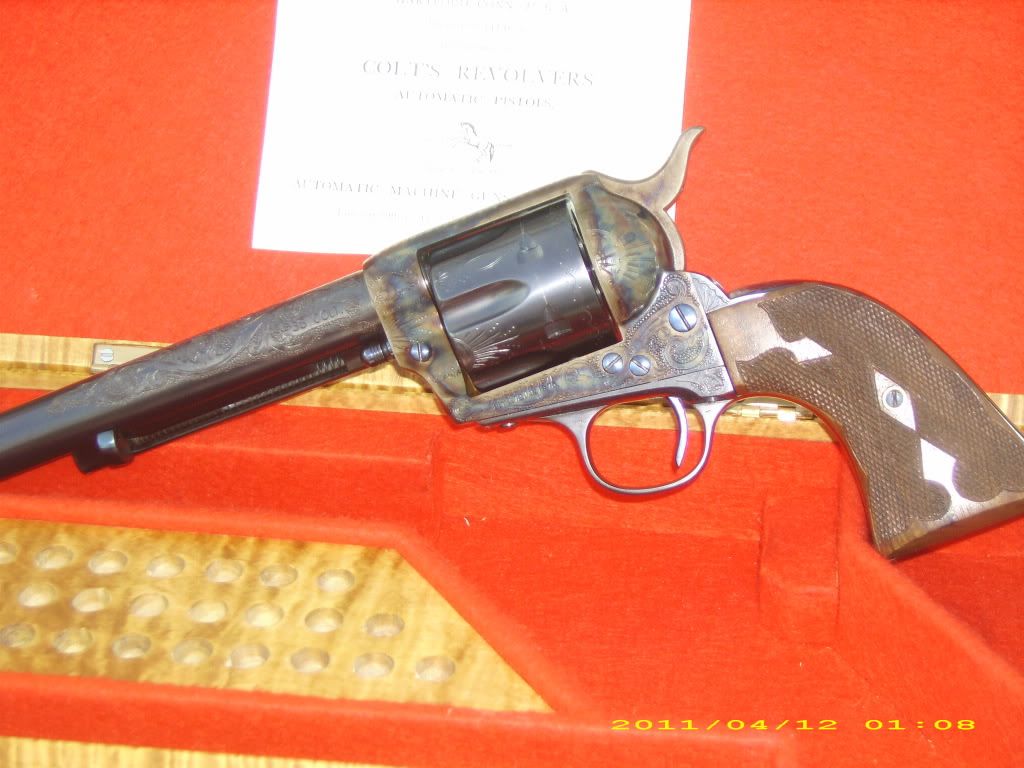

Anyway I'm posting a picture of a parker trigger guard that i believe is the right color. It may look lighter in color because of the outside light but it is quite dark.

"Anyway I'm posting a picture of a parker trigger guard that I believe is the right color"

----------------------------------------------------------------------------------------------

Very nice Doug, but I think that is a 16 ga. Sterlingworth trigger guard and not a Parker.......

"anyway i am posting a picture of a parker trigger guard that i think is the right color"

Very nice Doug, but I think that is a 16 ga. Sterlingworth trigger guard and not a Parker.......

You are correct, that's what I get for not paying attention. In fact I remember who's trigger guard it is now.

However it's the results I'm trying to show

Robert, thanks for the link. I will try a place near me for one. I bookmarked yours and will get it if the other one is not high enough.

I do have a face shield and welding gloves, and actually weldng jacket for protection, and will keep the oil far enough away as to be safe.

Thanks, and will post some pictures when I start.

David.......If you look around you can find a very good stainless thermometer made in the U.S.A that will last a long time, they are on Ebay used, at Midway new and so forth....... Just my opinion......

Regards,

Doug, before I retired I worked in a gererating station that supplied electricity to parts of N.J. Our plant was one of two coal fired and the technicians used Tel Tru gages. In our nuclear stations they also used them, so they must be of good quality. I will look for one that goes to 1000 deg.

Got mine from Brownells with a dandy mounting-clip for the tank side.

Here is the Marlin

Very nice Shawn...great work,..... The Marlin 1894 bolt was much blacker I believe, probably the light as you mentioned.....

Here are a few that I rebuilt. I try and keep the blues a softer blue/black as did the factories, remembering that these guns were mass produced firearms.

The Remington .22 pictured was trashed and needed a complete refinish. Rust blued the barrel/mag tube and hot blued the action. 1911 manufactured Remington model 12 with a full crescent butt plate.

The LC with a case colored forend iron is an ejector 12 bore. 1926.

The last LC Smith is a 16 ga. field grade. Extractor. 1931

1892 Marlin .32 CF...following post.

Here are some pics, CCH temps close to yours as you posted, except the drop before quench, I don't drop the temperature..... Rust blue and wood re-finish as well.

12 ga.

16 ga.

16 ga.

Best,

Nice work guys.

I found a temperature gage on eBay. Buy it Now or Make Offer, made offer and accepted $30 with free shipping. It is a Weston gage, 200-1000 degrees with a 3" face and 9" stem.

Had a choice of gage face either horizontal or vertical and picked vertical to stem. Figured it might be easier to look at and less likely to bump it.

Hopefully by Saturday or Monday will have it and will post some pictures of results.

Doug,

Your guns look very nice. I need to practice taking better photos. I agree that my Marlin colors are a little off. It was the first Marlin that I colored and I was still experimenting with shielding. I used a 2:1 wood to bone charcoal ratio for the Marlin. I colored the SAA several months ago and had learned more about shielding by that time. I used a 2:1 ration for that gun too and quenced at a higher temperature than I ususally do. It has too much green for Colt colors in my opinion. The Bisley I did three weeks ago. I used my usual quench temperature and a 2:1 charcoal ration. I got fewer greens and much more Colt like colors. I am still experimenting with the process.

Nice work guys.

I found a temperature gage on eBay. Buy it Now or Make Offer, made offer and accepted $30 with free shipping. It is a Weston gage, 200-1000 degrees with a 3" face and 9" stem.

Had a choice of gage face either horizontal or vertical and picked vertical to stem. Figured it might be easier to look at and less likely to bump it.

Hopefully by Saturday or Monday will have it and will post some pictures of results.

Fantastic David........that is a very good gauge..........U.S.A.

You'll be cookin' now...............Be extra careful with the hot salts as everyone above has mentioned.....

Keep us posted, looking forward to the pictures....!.......

Cheers,

Doug,

Your guns look very nice. I need to practice taking better photos. I agree that my Marlin colors are a little off. It was the first Marlin that I colored and I was still experimenting with shielding. I used a 2:1 wood to bone charcoal ratio for the Marlin. I colored the SAA several months ago and had learned more about shielding by that time. I used a 2:1 ration for that gun too and quenced at a higher temperature than I ususally do. It has too much green for Colt colors in my opinion. The Bisley I did three weeks ago. I used my usual quench temperature and a 2:1 charcoal ration. I got fewer greens and much more Colt like colors. I am still experimenting with the process.

Thank you Shawn..........we all experiment changing the ration, CCH is like a snowflake, no two are alike........all the castings and alloys are different as you know, even with the same manufacturer.

Your work really looks nice Shawn. Labor of love.

Best Regards,

One queston I have regarding this Nitre Bluing process, will it affect any parts that are case hardened? I want to Nitre Blue the top lever, and it is case hardened.

I know the shaft is. I took a hammerless top lever and shaped it for a hammer gun. The top part was workable and to me I was able to file it with no problem and I don't remember if in the begining I had trouble breaking through the skin.

David:-- ..If you didn't remove the skin all over the lever top surface, it probably won't blue right for color ...........you could gently bead blast it on low pressure, then take it down with 400 w/d for a decent surface, then hot blue it, should be o.k.

You've seen case colored guns that have been blued....some look real lousy and some blue o.k., but still look nasty to me, JMO.

Did you file all over the top surface while reshaping it and remove all the case skin...?....

Hope this helps.....

Best,

Doug, the thing I was worried about is the temperature of the bath annealing the case hardening.

The top lever that I made from a hammerless one, I used cold blued it a few times and it matched the rest of the metal ok.

I just polished this one and it came out shiny. The bluing on it wasn't too bad for a gun built in 1901.

I buy these "klunkers" as Russ Ruppel used to call them, and it gives me a chance to work on them and fix them up.

In the last year or so I really got into hammer guns, and like the pre-1897 ones with the back action locks. But if the price is right, I will get the later ones like this one.

Doug, the thing I was worried about is the temperature of the bath annealing the case hardening.

David.....annealing takes place at 1450 F with an 8/10/12 hour slow temperature descent (cool down period in the furnace), so blueing at 6-7-even 800 F is o.k. and the hardening (temper) of the shaft/lever will not be lost.

Cheers,

David,

I have successfully nitre blue hardened parts one of two ways. The first is to nitre blue the part with a first pass. Usually the first blue will have a light blue grey color with patches of blue-black. Next, polish off the blue with 400-600 and reblue. Often times the second blue takes. I believe that this works because the heat from the first blue tempers the steel. Sometimes this doesn't work very well on all steels. The second method I have used is to put the parts in the salt bath several times without polishing between blues. Each time more blue builds up. This is the only way I have been able to blue 2nd generation SAA cylinders. I have to experiment with temperatures but hardened steels will usually turn blue-black somewhere between 750-850F. Good luck.

I have a gunsmith acquaintance who claims to have spoken with a former employee of Turnbull. According to him Turnbull uses 825F. He said the employee claimed that Turnbull used what he described as a "yellowish liquid salt bath" to charcoal" blue and not charcoal. The former employee would not tell him what the salts were. The "yellowish liquid salt bath" sure sounds like nitre salts to me. I have no way of knowing if this is true or not. It was just what I was told second hand.

Note that even though full annealing will not take place raising the temp of a hardened part will draw or temper the hardness. Raising a case hardened part to 750-800°F will definitely temper out the "File Hardness" it obtained on quench.

Personally I would not see this as a problem on the top lever, but is a definite reason for not "Torch Coloring" frames. Likewise I would personally not want a double frame which was originally case hardened, even if I were willing to switch to a blue color ,done by any method which exceeded 300°F.

Shawn, thanks for the information. I don't think I will go that high, 825.

If worse comes to worse I will cold blue it a bunch of times, or I will harden a piece of drill rod and draw it back to about 600 deg, which should be blue, and try that first.

The only thing bad about that is they are not the same compositon. I believe L.C. Smith used mostly 6120 on a lot of their case hardened parts, and the drill rod definitely has more carbon content.

Miller, That's want I thought. And yes, does it make a difference? I don't believe so. I'm wondering if Hunter Arms did polish the top of the lever and when case hardened, it turned that blue when annealed.

David,

I have a gunsmith acquaintance who claims to have spoken with a former employee of Turnbull. According to him Turnbull uses 825F. He said the employee claimed that Turnbull used what he described as a "yellowish liquid salt bath" to charcoal" blue and not charcoal. The former employee would not tell him what the salts were. The "yellowish liquid salt bath" sure sounds like nitre salts to me. I have no way of knowing if this is true or not. It was just what I was told second hand.

Nitre bluing at 825F just to say its charcoal bluing seems like a waste of money in my opinion. You might as well be actually charcoal bluing the parts at that temperature and if they were going to say one thing and do another why not just save yourself some time and money and black oxide the parts at 295F and call it charcoal bluing. Im not calling anyone a liar or sticking up for anyone, Im just interested by the story.

Channing Will

I can put this to rest. I used to work for Doug and can say that all of his finishes are as advertised - including charcoal blue.

Best, Dan

Dan,

Could you tell us more about Turnbull's charcoal blue process? I was told that by the late Bill Adair. He said that a former Turnbull employee told him that but had no way of verifying it. I guess that now We know it is not true. Thanks

Shawn,

I worked as a stockmaker for Doug so I was never taught any specifics as to the metal finishing processes (nor would I divulge any trade secrets of Doug's)! But I can tell you with total confidence that charcoal bluing was (and I'm sure still is) done in the traditional process using charcoal and oven. Nitre bluing was of course also offered but was reserved for smaller parts and the blue was generally the lower heat bright blues most associate with nitre.

Best, Dan

Thanks Dan.

I've discussed the subject many times, at length with Doug and have had many parts finished by most all of his methods and was about to call bullsh!t on that third hand BS.

Hagn action color case hardened by Turnbull Restoration with a request for muted colors. And it's hard too. Turn-around; MT to NY to MT, less that 30 days.

Thermometer came today. Built a holder for it and a place to hang parts from.

I had two bottles of stump remover (potassium nitrate) and went and bought another. Pourng the two bottles of crystals into the loaf pan brought the level to about 1 1/2" from the top. Added a little more and set on the burner. Partially disolved at 600 deg and fluid was dark, a few minutes later it was better, more translucent, but the tmeperature would not go above 600 deg. Started with triggers, left in about 6 minutes, took out and quenched in oil, left a heavy film of junk on them. Did a few screws, and quencehd them in oil also.Did the top lever, left in longer but this time I flushed it with water, took the scum off under the water. Did the trigger guard, left in about 10 minutes,, but the wires weren't long enough so I fastended the "S" hooks on the side, but the tirgger guard was on it's die also. When finished it came out blotchy.

I am fairly happy with the screws, the tip lever, trigger guard will have to be done over when I find a burner that will go higher. It states on the side of the burner case that the output is 34k/btu hr. I was only using one burner of the two. What should I look for as to output of burner/s?

Had a fan behind me blowing out the door. Used safety glasses and a face shield aldong with welders gloves.

I have to go get another bottle of stump remover to bring the level up. That would be 4 total in a pan that measures 10" inside x 4" wide x 3" high (approx)

Also do you have to polish the parts after? Mine had a matte finish on them, I buffed them with a rag and they looked much better.

David, several years ago I did nitre blueing mainly on double trigger guards. I used a cast iron dutch oven with good results, is it possible the container you are using is too light and won't retain the heat? My heat source was an old cast iron 2 burner gas set up

James, that is possible, but Brownell's sells a welded pan that doesn't look that thick. It's probably 1/16" or so.

I think I need a bigger burner. The temperature held at 600 the whole time I was coloring.

David:

I think you need to use a round pot that is shaped the same as the burner and doesn't waste the heat.........Watch the Nitre Blue video again...... Your burner looks big enough to me.....

Doesn't look like the 'stump stuff' is melting quite right...?..........

Clean/cool the parts in a bucket of water, polish and then oil the parts after they are clean and cool (I wax mine).

Hope this helps.....

Best,

Doug, The flames where comes up the sides and you are most likely right in getting a bigger round pot.

The crystals were melting and then the liquid started coming through the film of crystals starting at the sides. I stirred them with that piece of brass filler rod you see on the other burner. I did this until the whole thing turned liquid.

The color as described in another post was dark, it lightened up also as described in that post.

The water quenching seemed to be better as it took that film of solitified liquid off. The oil quenching left the film on and to get it off I lightly heated the parts with a propane torch and then ran them under water. The stuff came off easily with a scrub brush. Polshed with a rag.

Why do you think the trigger guard came out blotchy? Maybe because it was on it's side resting on the bottom of the pan.?

I think the screws came out decent, more black than bluish.

Also do they all have a matte finish when removed from the bluing solution?

Why do you think the trigger guard came out blotchy? Maybe because it was on it's side resting on the bottom of the pan.?

I think the screws came out decent, more black than bluish.

Also do they all have a matte finish when removed from the bluing solution?

David:

Probably because the impurities in the 'stump stuff' had not yet burned off or because you hit the trigger guard with oil while it was still hot.....or an uneven temperature....you should let your stump stuff burn off for an hour or so before using it the first time.

The parts would have been more blue had the temp been constant and probably higher.....again, a large round pot covering the burner should do the trick......

You will need to play with it a bit to define your process with your specific set up, always the case......when you get the temperature set and constant the parts will come out with more shine......

also the better the prep polish, the better the

final finish .....

Cheers,

Thanks Doug. Headng to the store for a round pot, hopefully maybe a cast iron one.

I do think the temperature should be higher, and hopefully a round pot will catch the flames better and hold the heat.

Let you know how it works out when I get going again.

JD, When fully up to temp the pan will have a slightly amber colored fluid in it, no globs of unmelted salts.

My burner is rated at 10,000 BTU,under a round stainless steel dog dish.

When first immersed in the salts it will congeal on the part due to its lower temp,preheating the part will help reduce this. As it comes up to temp the salts will melt back off and bubbles may appear, these must be dislodged or they will cause spots. Any oil on the metal will cause splotches. The gunk after quenching is congealed salts that will rinse right off under warm water. HTH Robert

Robert, great information. At slightly lower than 600 deg., the salts started to turned amber colored, at 600 deg. the salts were a nice amber and everything was liquid. The temperature would not go higherthan 600 the whole time. Doug stated he thought my burner was big enough, but the pan should have been round to cover the burner. I agree with that now.

The quenching in the oil did result in some congealed build up and I just ran it under cold water, didn't work. Heated it slightly with torch and then flushed with water, better. I will try the warm water.

Right now looking for a round pan, and the stainless dog pan like yours might be it.

I buffed the parts using some rouge and the triggers came out nice, the one screw that I made came out good also. The trigger guard, not bad, and I'm not sure if I will do that again. Still have to do the for-end metal and that will be the one part that hopefully will come out good.

I will post the results.

Metal has to be absolutely clean. Cleaner than you would accept for hot blueing purposes.

Don't let it sit around after final polishing. Even an unseen to the eye oxidation starting to form will cause a poor blue finish.

Insulate the sides of the pot you're melting the salt in if you can. We used to use the all purpose asbestose paper. But since that stuff is more hands off than a hypo on the sidewalk, there must be something else available now.

A steel heat shield around the sides with a layer of insulation helps dramaticly in heat up, stability of temp and being able to reach the higher temps with a common heat source.

Have some absolutely dry and oil free fine steel wool handy for the small air bubbles that will sometimes form on parts in the salts.

Sometimes just lifting the parts and carefully dunking them back and forth into the salts will break up the bubbles. If needed, swipe gently over them with just a wisp of the steel wool snagged around the end of a new clean bronze cleaning brush on a pistol cleaning rod for easy handling. It can get hot quick too, but you're wearing your gloves right!

If the part doesn't color to your expectations, it'll need to be polished up again to be redone. Trying to touch up a spot or two never seems to work out well.

Plain sodium nitrate works fine. Ammonium nitrate works well too. Most any chemicle salt that'll melt around 350 and not boil till after 900F can be used.

The Brownells stuff works good. I've used it & plain sodium nitrate both for many years for straw & blue all the way to a charcoal blue look at 825/850F.

Works nicely as a spring temper medium in the lower ranges.

Ammonium Nitrate was used in a pinch a couple of times and it worked just fine too.

Some metals will just not blue well with the process due to their alloy content or heat treatment.

We used both nitre and at the time the start of a charcoal blue process at DTR.

Charcoal blue was done with bone char (same stuff from the CCH process) and a Mobil synthetic oil (can't recall the #) in the place of carbonia oil of the original process.

The charcoal blue process was done in a self contained canister type device we fabricated. Air tight with the exception of a tiny hole in the removeable end to allow the smoke out and (hopefully) no atmosphere in.

It was placed inside one of the existing CCH ovens.

It was more a mimic of the later carbonia oil process of the American Gas Furnace Co., than the earlier real charcoal bluing process.

Two different processes giving similar results. One replacing the other as more labor & time efficient in industry in the early 20th Century.

The canister had to be manually rotated a 1/2 turn every 20min IIRC. The batch ran for 2hrs to complete. Results were at times spectacular, other times not acceptable for a number of reasons. Usually air leaking into the canister around the cover gasket somewhere, moisture in the char/oil mix, improper mix, parts not clean,temp not correct,,lots of variables..

But we were on the right track. Then it went into secret mode for refinement like most things there.

That was in the early 90's. I don't know what process(es) they use over there now.

Like CCH, it's not a terribly complicated process. Just one that needs constant repetition once a system that yields good results is found.

Kutter, thanks for the loads of information. I will copy that to what I have already.

I went and got a round stainless dish, about 9" in dia. and 3" deep. Mounted my old hardware on it and had removed the old salts from the other pan. This was 3 lbs of salts and I bought another one just to make sure I had enough. When it all melted I barely had enough in there, (where the heck does it go).

Temperature still would not go above 600 deg. So now I'm blaming it on the burner (what else?).

After everything melted and when the bubbles stopped, it was a nice amber color (as described by Robert-Highstrap) and you could see to the bottom.

I did the for-end and it came out like the trigger guard. The knuckle area after I buffed it didn't look bad but I know I need higher temperatures.

I will experiment more. I put the gun together, looks a whole lot better than when I got it. Still a "klunker" but one that I won't mind being seen with. I rusted the barrels but only 4 rustings, 3 boilings and 1 etch. Could have gone more, but good enough for this application.

I wish to thank everyone for their valuable information. I will keep on trying and will post when I get right.

JDW

I just read the last page, only, on this thread as it caught my interest. I'm not experienced in this process, but something struck me as a possibility for your "blotchy" part. You mentioned you used rouge.

I recall from my past an admonishment about using wax based rouge for polishing parts to be blued. My understanding is that it cannot be cleaned completely since high speed buffing with wax rouge puts the rouge into the surface. Others will know better than I on this point. If you don't get any feedback here, call Brownells and ask their tech assistant line.

Chuck, I used the rouge after I nitre blued them. The polishing helped somewhat and did made the triggers look good. The trigger guard and for-end, I believe it was from not having a high enough temperature.

I polished all the parts with emery cloth.

The one funny thing is I made a few screws to replace the buggered ones taking it apart. I had to drill them out to remove them, could not budge them with the drill press method and broke a few bits trying. Anyway I used drill rod as I didn't have any mild steel big enough to make them. The top lever plate screw nitred ok, the front trigger plate screw would not take the bath, stayed shiny even after a repeated cleaning and re-dipping.

Will Sodium or Ammonium?? Nitrate work in this process??

Sodium and Potassium Nitrate are called "saltpetre"

Looking up KNO3, it is Potassium Nitrate, also known as saltpeter. Sodium Nitrate is NaNo3. Ammonium Nitrate is NH4NO3. I don't believe they can be used for bluing, only the KNO3.

Sodium Nitrate is used in processed meats. This infomation is what I received when I typed in the various nitrates in Ask Jeeves- Ask.com

Many years ago when onthe farm & we butchered our own hogs we used saltpeter (Potassium Nitrate) in a recipe we had for Sugar Cured Hams. Chille was at least at some point in time a major supplier of Sodium Nitrate so it has often been referred to as Chile Saltpeter.

Any of the three can be used in Hot Salt bluing & are sometimes mixed. I have no idea though as to whether either of the alternates are compatible with Niter Bluing.

Ammonium Nitrate works fine.