|

S |

M |

T |

W |

T |

F |

S |

|

|

1

|

2

|

3

|

4

|

5

|

6

|

|

7

|

8

|

9

|

10

|

11

|

12

|

13

|

|

14

|

15

|

16

|

17

|

18

|

19

|

20

|

|

21

|

22

|

23

|

24

|

25

|

26

|

27

|

|

28

|

29

|

30

|

|

|

|

|

|

|

Forums10

Topics38,468

Posts545,136

Members14,409

| |

Most Online1,271

55 minutes ago

|

|

|

|

Joined: Feb 2008

Posts: 1,117 Likes: 26

Sidelock

|

OP

Sidelock

Joined: Feb 2008

Posts: 1,117 Likes: 26 |

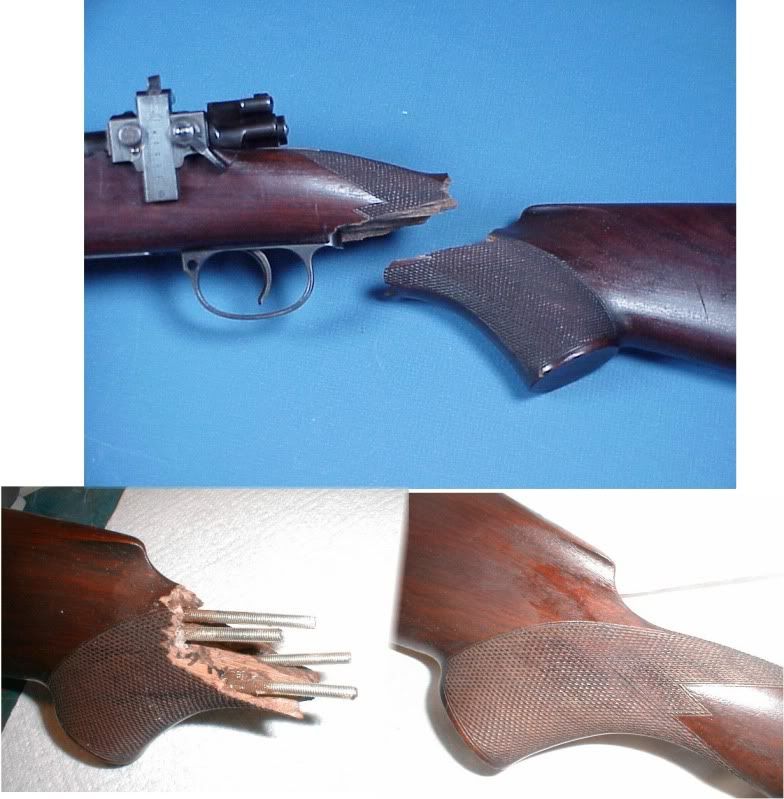

Sadly, I just received a little prewar combo gun in 16/25-35 with a stock broken clean through at the wrist. I have contacted several stock men about repairing it, and they seem to be of two schools of thought in terms or reinforcing the break: They use either several pieces of threaded steel rod just under the surface of the wood, or a hardwood rod in the center of the break. In both cases epoxy is used as an adhesive. In particular the wood rod proponents do not have kind things to say about the steel reinforcing clan. Could some of you who know based upon actual experience render opinions? I would have the stock replaced, but a new stock will cost 2-3 times the cost of the repair, and the economics won't justify it.

|

|

|

|

|

Joined: Nov 2006

Posts: 3,436 Likes: 34

Sidelock

|

Sidelock

Joined: Nov 2006

Posts: 3,436 Likes: 34 |

You could split the difference and use carbon fiber rods with the epoxy adhesive.

|

|

|

|

|

Joined: Dec 2001

Posts: 3,574 Likes: 87

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 3,574 Likes: 87 |

Vol I've had stocks repaired using the steel rod method and have never had one fail me. I have not used the other method.

|

|

|

|

|

Joined: Jan 2002

Posts: 527

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 527 |

I use aluminum / brass rods / tubes etc. epoxied in place for any of my repair work. --- John Can.

|

|

|

|

|

Joined: Jan 2002

Posts: 13,149 Likes: 1147

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 13,149 Likes: 1147 |

I recently saw the buttstock of a Fox HE that had been broken at the wrist and had been repaired many years ago with four brass rods that went from the head of the stock all the way down through the wrist. They appeared to be set in some type of hardened glue. The repair was so old that I can't surmise that it was epoxy (maybe epoxy is older than I think). I was impressed with the repair, but came away thinking that I would probably use aluminum rods to keep from altering the weight significantly. When repaired with a cyano-acralate like Zap-A-Gap and pinned through the wrist like this I can see where the repair would be much stronger than the original stock itself without altering the handling characteristics of the gun.

Last edited by Stan; 12/03/09 07:19 PM.

May God bless America and those who defend her.

|

|

|

|

|

Joined: Dec 2001

Posts: 6,881

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 6,881 |

Threaded steel and epoxy!

MP Sadly Deceased as of 2/17/2014

|

|

|

|

|

Joined: Jan 2002

Posts: 2,752

Sidelock

|

Sidelock

Joined: Jan 2002

Posts: 2,752 |

Vol:

If its done correctly, I think you will find its 6 of one, half-dozen of the other.

The ONE caution I have encountered with the "steel fix" approach is that as the wood shrinks and swells with changes in humidity, the steel may have the opportunity to get loose in the stock, whereas the wood dowel will ( theoretically) take on or give off moisture at about the same rate as the surrounding original stock material, thereby remaining "tight". I have no idea if this is a real concern, and I do not have any experience with the steel rod method, so I cannot tell you firsthand.

I have used the wood dowel method to repair the fragmented stock of an 1840's era muzzleloader but I have not shot it since the repair. A friend who frequents this board, Doc Bill, has used a plywood insert to return a badly battered and completely broken and shattered early Lefever stock to service. He shoots the gun a lot, and it works.

On the other hand, Friend Petrov, as demonstrated above, knows what he is doing and uses the steel rod method.

So... my guess is use whichever method is most convenient, just do it right and make sure the epoxy is mixed correctly.

My thoughts, anyway.

Regards

GKT

Texas Declaration of Independence 1836 -The Indictment against the dictatorship, Para.16:"It has demanded us to deliver up our arms, which are essential to our defence, the rightful property of freemen, and formidable only to tyrannical governments."

|

|

|

|

|

Joined: Feb 2008

Posts: 518 Likes: 4

Sidelock

|

Sidelock

Joined: Feb 2008

Posts: 518 Likes: 4 |

It's not a nice situation to be in, but I've used carbon rods with good results. They come in a variety of diameters, are tougher than hell, easily shaped with a file or Dremel, and like epoxy.

|

|

|

|

|

Joined: Mar 2006

Posts: 104

Junior Member

|

Junior Member

Joined: Mar 2006

Posts: 104 |

UPS broke my J P Sauer hammergun stock through the wrist. I had it repaired, and the stock maker used a walnut biscuit about 1/4' by 1.5". It broke again. I removed the trigger guard, and chiseled out a mortise 3/8ths" wide by 5" long by 3/4" deep. This entire mortise would be covered by the trigger guard.

I held the two pieces of stock together with a clamp. and made a cast of the mortise. I made an exact duplicate of the cast by grinding and filing a piece of aircraft alluminum bar stock. I ground channels all around it for the epoxy to flow and through and grip on to. I used acra glass as the bonding agent. The stock seems far stronger now than ever, and the repair is completely unseen when the trigger guard is in place. I am having a new buttstock and forearm turned before anything else happens, but I am confident this repair will hold.

I can't be too bad, my dogs will kiss me.

|

|

|

|

|

Joined: Dec 2008

Posts: 571 Likes: 9

Sidelock

|

Sidelock

Joined: Dec 2008

Posts: 571 Likes: 9 |

I have performed the fix using the four steel roda method shown above. It has held with no problems.

|

|

|

|

|