One of the difficulties that has to be over come to produce damascus is controlling the output of the smelting process. Both steel and iron have to be produced to create damascus. This takes a high level of technology. We know that this level had been reached in Europe shortly after firearms were 1st introduced.

"Some Aspects of the Metallurgy and Production of European Armor"By Craig Johnson, first published in the Armored Proceedings Symposium Notes, 1999.

The processes for turning iron ore into a workable material were known throughout Europe, Asia, and the Orient since antiquity. The product that was normally produced was wrought iron and later cast iron. Wrought iron never achieved a fully liquid state. A furnace held in the 1100°C to 1200°C (abt 2000°F-2200°F) range would allow the reduced iron particles of the ore to coalesce into a mass with the majority of the silicates liquefying and draining away as slag. What remained would be a spongy looking mass called a "bloom," the refining of which was accomplished by heating and hammering repeatedly to drive additional slag out and close any voids, resulting in a bar or plate of wrought iron. Iron produced in this way consists of large ferrite crystals and some slag inclusions and would have to be carburized to achieve a steely state. This carburization may have been accomplished in the furnace by lengthening the time the bloom is left in, tempreture increases or increases in the ratio of fuel to ore

.....

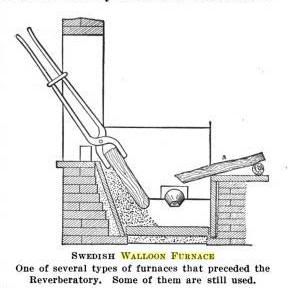

Cast iron needs the reverse process to be usable as a steel product. The material needs to be reduced in carbon content and this is usually accomplished by passing air through a stream of the liquefied iron onto a charcoal hearth, known as a finery, or "Walloon Furnace". There is some conjecture that such a process was being used in the pre Alpine valleys as early as the mid 13th century. By the 15th C. the Northern Italian production centers were casting iron cannon, which may indicate the technology was available in previous centuries to manipulate liquid iron. This also may have been the process used in Styria. The method for decarburisation by forging together cast and wrought iron and allowing carbon diffusion to take place resulting in a steel material is described by Biringuccio in Pirotechnia (1540) though this would be a difficult proces to control. Some have thought this maybe the "Brescisian Process" but this was probably a finery of some sort that was misunderstood by Biringuccio. The "Brescisian Process"may have been a source for the large amount of steel needed by the Milanese armorers.

La Verne Ward Spring

http://books.google.com/books?id=7YJCAAAAIAAJ&pg=PA93&dq=Walloon+Furnace#PPA94,M1

The concept of the Walloon forge reached it's zenith in the Bessemer process.

Pete