|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

|

|

1

|

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

|

30

|

|

|

|

|

|

|

|

|

Forums10

Topics38,576

Posts546,564

Members14,424

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

I've been doing quite a few barrels in the past year. I've been using the methodology from the many refinishing documents like Flannigan's and Gaddy's found on DocDrew's site, as well as many other's found in books like Angier's, as well as from my collection of Vintage gunsmithing books. It seems like I've hit all possible internet sources as well. There's some "holes" in the specific methodology described, this thread is designed to fill one of them in, it's specifically about solution strength and it's effect on pattern throughout the rusting and etching cycles. All this directly relates to boiled black/silver barrels.

One of the points throughout the listed methodology is the need to start out with strong rusting solutions, and to use progressively weaker solutions as the cycles progress. There is no real specifics in regard to this, so I'm going to describe what I've found.

Initially, I used to plan for a minimum of six cycles for Twist barrels, and nine to twelve for Damascus. For all barrels I used an initial etch before rusting to bring out the pattern. For Damascus I would rust full strength for three cycles and etch, then then drop solution strength by half for the fourth through sixth cycles and follow the same 50% strength decrease for each additional three rust/etch cycles. I now realize that this concept is not optimum. What would usually result is that the barrels would develop very nice color, but the bluing was fairly dark with only limited pattern visible. I would then rely on the last etch to bring out the pattern and contrast. Often, it would result in a degradation of pattern, with patchy, streaky and unacceptable results. I knew Flanigan was achieving nice contrast early in the process, so I started varying methodology. This is what I've found, resulting in the filling of the methodology hole.

I found it is important to drop the solution strength in half with each of the initial rusting cycles. I now use only one rust with 100%, 50%, and 25%. I then etch. I use a fairly weak Ferric Chloride etch, about 3%. Usually for one minute. This brings out the pattern well and sets it up for additional cycles, all at 12.5%, or one-eighth strength. It's also easier to do an additional etch if necessary, since the etch strength is fairly weak. You can't use weaker rusting solutions initially, as they create blotches. Once you're to the 1/8th strength, the rusting is actually visibly different on the iron vs. steel layers, and the contrast actually improves with each cycle. Additional short etches with the weak acid nicely brings out more contrast, avoiding the degradation of pattern and the resulting streaks and blotches.

Regards

Ken

Last edited by Ken61; 04/14/15 08:34 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Dec 2001

Posts: 7,000 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 7,000 Likes: 402 |

Good information Ken. I had an employee who was doing the process in my shop for about 5 years. He got excellent results but it was very labor intensive. He usually had 15 or more passes and he also reduced the acid strength as the number of passes increased. I believe he stuck with stronger acid for more passes than you are using. This may very well have contributed to amount of work required with his process. I'm getting ready to give it a go myself and I'll give your method a try and report back.

Are you using a 3% ferric chloride dip for all stages or just the first dip? My former employee varied the strength of the Ferric Chloride as well as the strength of the acid.

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

I'm using it for all stages, although sometimes I use a copper sulphate/NaCl (Bordeaux) etch initially. For the ferric chloride, decreasing the strength gives a little more control since it becomes a matter of etch duration, erring on the side of caution and opting for additional etches instead. Finer Damascus requires more cycles, a 2-iron Crolle barrel such as from an LC 0 or Remington KED requires fewer cycles than say a finer 4-iron set like a Parker D, or even a 3-iron "Washington" set. The finer the pattern, the more cycles needed to bring out the detail. On the last 4-iron set I ended up going 16 cycles.

One thing I usually do, as per Flanigan's tutorial, is not boil until The pattern is where I want it. Careful inspection and carding during the first rust or two is imperative. Inspection under magnification is helpful to make sure there are no streaks or patches initially. If they exist, they'll only get worse after boiling. If after say, the third rust they exist, it's better to strip back down and begin again. You'll actually save time rather that trying to overcome faults throughout the process. You don't want to get to the end and have visible faults, I guarantee you won't be happy. If you have rib leaks, be sure and correct them initially with some shellac down the void, as etchant leaking out is a sure way to bugger the pattern.

Last edited by Ken61; 04/14/15 01:41 PM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Dec 2001

Posts: 7,000 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 7,000 Likes: 402 |

Ken,

I read through your post again as I'm running my test pieces currently and noticed what you said about boiling at the end. I'm not going to do the black and white pattern right off the bat but am starting with a traditional brown and white found on British guns so will not need to boil. Are you wet carding after each rusting or only occasionally in problem spots? I'm using a modified version of C26 from Angier's book, No mercuric chloride. Starting out with 50% solution which is still very strong and reducing from there. What solution are you using for rusting? My first test piece is fairly course and the pattern shows pretty darn well after a single pass. Fun stuff.....

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

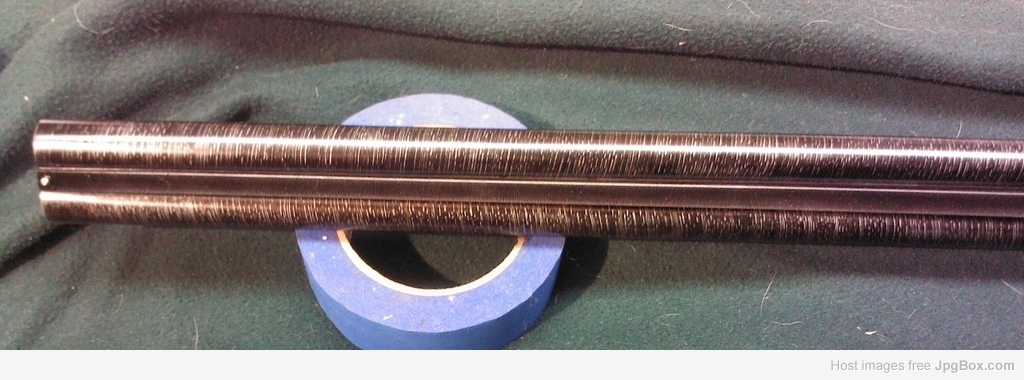

Actually, lately I've been using a modified form of the Original Parker Process. The one that Dr. Gaddy described in DGJ back in 2003. Are you familiar with it? I've gone to the five-minute battery acid soak initially, then application of the two solutions for each cycle. I'm going to be working up a thread on it eventually. Where did you find Spirits of Nitre? For brown and white I'm using C.19. It gives a nice color. For all barrels I now scald after rustings, rather than boiling. A 10 minute soak in hot tap water with a water change at the half-way point enables a partial conversion of the rust. It was too hard for my wheel to remove it easily without it. I also use C.10.C quite a bit, for black and white, it gives a nice deep color. I've found that the first of the two Parker solutions (CuSO4 & HCL) works as an etch, causing pattern to develop earlier. It just has to be applied with a well squeezed sponge. It also usually eliminates the need for intermediate etches, as the logwood boils at the end (up to three) contain Copper Sulphate as well, providing more etching action. One thing I've gone to that I really like is using Calcium Carbonate to scrub the barrels with after each etch or logwood boil. Rather than buy Whiting I'd have to order, I use powdered Lightweight Drywall Compound which I mix up as a paste to rub on the barrels. I think it's much better than baking soda, a little less abrasive so there's less chance of disturbing the pattern. Hope I answered your question. Here's a set of Syracuse New Twist tubes I used the process on.   Regards Ken

Last edited by Ken61; 06/27/15 08:37 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Dec 2001

Posts: 7,000 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 7,000 Likes: 402 |

Ken,

I picked a several lifetime supply of Nitric Acid about a dozen years ago from a local guy who ran a chemical supply company. I have managed to lose his contact information but I have some to spare if you are in need. I mixed this stuff forever ago but pretty much used Gaddy's recipe, minus the Mercuric Chloride.

I have read through both Gaddy and Flanigan and have not found the original Parker formulas you refer to. Where did you find them?

Barrels look very too!

Steve

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Thanks for the offer,

I have lot`s of both Nitric and Hydrochloric acid. The Parker method was published in DGJ in 2003. It's worth the read, with the few modifications I made it works really well. Like Gaddy, the rusting solution composition probably isn't real significant, but the initial etchant applied to the tubes before it certainly is. (my opinion) It's merely 1/2 oz of Hydrochloric Acid and 1/2 oz of Copper Sulfate in one quart of water. Applied very lightly to avoid copper deposits, and immediately followed by the rusting solution. This is essentially an etching, rather than a rusting solution and results in a nice pattern throughout the rusting cycles. It also means you can keep the rusting solutions strength stronger throughout the process, as opposed to using intermediate Ferric Chloride etches to bring out the pattern.

I consider Copper Sulfate in the Logwood solution to be essential as well. 60 cc/ml logwood powder, 30 cc/ml ferrous sulphate, and 1 1/2 oz of copper sulfate per gallon of soak. This creates a reddish copper "felt" accumulation on the barrels, but when scrubbed off with drywall paste it reveals the strong black and white contrast. Gaddy's article suggests taking even brown and white barrels through the logwood soaks, and then applying light rusting solutions to the tubes afterwards (no boiling) to achieve the desired brown color.

I went with solutions from Angier that I would be able to exactly duplicate. I chose that route rather than use solutions that I would have to omit the Mercuric Chloride from.

Regards Ken

Last edited by Ken61; 06/27/15 10:45 AM.

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Apr 2006

Posts: 717

Sidelock

|

Sidelock

Joined: Apr 2006

Posts: 717 |

Those barrels look familiar.... ;-)

|

|

|

|

|

Joined: Dec 2001

Posts: 7,000 Likes: 402

Sidelock

|

Sidelock

Joined: Dec 2001

Posts: 7,000 Likes: 402 |

Thanks Ken. I had completely forgotten about the third article Gaddy had written that focused on the Parker methodology. More stuff to play with.

Steve

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Those barrels look familiar.... ;-) A nice set of tubes. I'm holding them only because I have to shoot comparison pics between them and the "Old Twist" Hollenbeck barrels I have once they're finished...The lacquer is drying as I type..

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|

Joined: Sep 2003

Posts: 91

Sidelock

|

Sidelock

Joined: Sep 2003

Posts: 91 |

Ken,

Do you have a website?

|

|

|

|

|

Joined: Mar 2013

Posts: 2,862

Sidelock

|

OP

Sidelock

Joined: Mar 2013

Posts: 2,862 |

Ken,

Do you have a website? In the works right now. Feel free to PM me here with questions. It's easy to post pictures in a PM, so I can provide examples of things.. Ken

I prefer wood to plastic, leather to nylon, waxed cotton to Gore-Tex, and split bamboo to graphite.

|

|

|

|

|