A bit off topic...

Larry,

I think you are looking for revisions to the Brussels Convention. These happen on a regular basis. I know they issued guidelines in 1991. Not sure when the latest was.

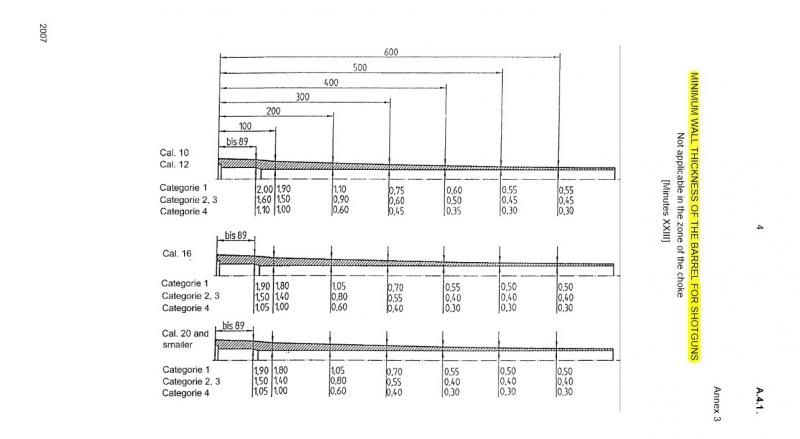

http://www.cip-bobp.org/sites/default/files/new_file/A-4-1_EN.pdfMinimum shotgun wall thickness by gauge and steel category.

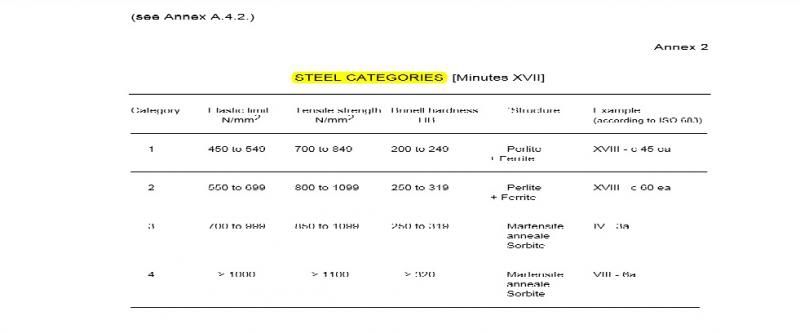

Steel categories.

https://en.wikipedia.org/wiki/Proof_test#cite_note-14

https://en.wikipedia.org/wiki/Proof_test#cite_note-14Under SAAMI proof test procedures, for bottlenecked cases the centre of the transducer is located .175" behind the shoulder of the case for large diameter (.250") transducers and .150" for small diameter (.194") transducers. For straight cases the centre of the transducer is located one-half of the transducer diameter plus .005" behind the base of the seated bullet. Small transducers are used when the case diameter at the point of measurement is less than .35".

Under C.I.P. proof test standards a drilled case is used and the piezo measuring device (transducer) will be positioned at a distance of 25 mm from the breech face when the length of the cartridge case permits that, including limits. When the length of the cartridge case is too short, pressure measurement will take place at a cartridge specific defined shorter distance from the breech face depending on the dimensions of the case.

The difference in the location of the pressure measurement gives different results than the C.I.P. standard

Videos of CIP proof testing

http://www.cip-bobp.org/epreuves%20videoPete