|

S |

M |

T |

W |

T |

F |

S |

|

|

|

|

|

|

|

1

|

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

9

|

10

|

11

|

12

|

13

|

14

|

15

|

|

16

|

17

|

18

|

19

|

20

|

21

|

22

|

|

23

|

24

|

25

|

26

|

27

|

28

|

29

|

|

30

|

|

|

|

|

|

|

|

|

0 members (),

254

guests, and

17

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

Forums10

Topics38,572

Posts546,458

Members14,424

| |

Most Online1,344

Apr 29th, 2024

|

|

|

|

Joined: Oct 2010

Posts: 969 Likes: 38

Sidelock

|

Sidelock

Joined: Oct 2010

Posts: 969 Likes: 38 |

Steve, have you found any information re the Philipsons? Like recent address etc. My searches have turned a blank.

The web of craftsmen involved in making a double was and is extensive in most gunmaking centers in Europe. This tends to deflate the notion that "in house" is somehow better.

Most gunmaking centers by custom allow craftsmen to have a second job. I have seen this in th UK, Spain and in Italy. When I ordered my SXS that was based on ideas set down by Gough Thomas, therefore not doable with the usual machining, I looked around for a willing maker. Castellani took on the job. However, the actioning was done by the Zanotti actioner. Bareling was done by someone else, engraving by Poli whose dayjob was at Beretta, the stocking by a lady who worked in her house, and the finishing by Castellani senior. This was usual in Gardone in the 80s.

The point is who takes responsibility for the finished product and carries it through proof and does any warranty work. That person/firm is the maker and entitled to stamp their name on it. Nothing wrong with that if we all know the score.

The best Holland I ever handled was reputedly built for a royal.It was displayed in an antique "salon" who allowed me to remove the locks and photograph the gun. The locks were stamped ASHES, the Brazier trade mark. I would bet that the barrel blacking was done in Wolverhampton and the color case hardening by Saint Ledger the elder. Still a Holland though!

|

|

|

|

|

Joined: Oct 2009

Posts: 531 Likes: 18

Sidelock

|

Sidelock

Joined: Oct 2009

Posts: 531 Likes: 18 |

Obsessed -

First - I had a 'senior moment' with 1906. I meant 1912. Only a very few were sold after that date. The "Top lever (new pattern)

ejector appeared in the books in 1910. I assume that was the "screw grip." Later in the books, it was identified as the "screw grip."

I wish I knew what "barrel filer and actioner" meant - but I don't.

|

|

|

|

|

Joined: Oct 2009

Posts: 531 Likes: 18

Sidelock

|

Sidelock

Joined: Oct 2009

Posts: 531 Likes: 18 |

Shotgunlover,

No address - just their name in the "Barrel filer and actioner" column of the serial number ledger.

|

|

|

|

|

Joined: Oct 2010

Posts: 969 Likes: 38

Sidelock

|

Sidelock

Joined: Oct 2010

Posts: 969 Likes: 38 |

Steve thank you.

I have heard the Philipsons name in connection with current production but cannot for the life of me remember where!

Actioner is the man who fits and assembles the action. Again, from the Shooting Times of old, there is a piece on one of the geat actioners within living memory, Bill Mealey, with a wondeful picture of his gnarled hands daintily fitting a lock spring. After many totally amateur tries at lock making, I know how hard it is to do it right. It is all stuff they do not teach you in metal work at school.

|

|

|

|

|

Joined: Oct 2006

Posts: 1,544

Sidelock

|

Sidelock

Joined: Oct 2006

Posts: 1,544 |

HomelessJoe, In all the years you and I have shared this board, I do not think you have ever written anything I thought constructive or useful. However, on this point you and I are in agreement, it must be Christmas!

One does need to be careful here - action forgings from the like so of Phillipson were bought by the gun trade at large, bigger factories made their own for a time. One must not confuse the making of the forging with the filing up of the action.

All the manufacturing companies, and many small firms had actioners, whose job it is/was to make the basic gun into a gun shape from forged parts. Buoying barrelled actions, part-finished or completely finished guns from major factories took of in a major way in the 1880s. It was not uniform. Everyone did what they wanted on a particular order.

|

|

|

|

|

Joined: Oct 2010

Posts: 969 Likes: 38

Sidelock

|

Sidelock

Joined: Oct 2010

Posts: 969 Likes: 38 |

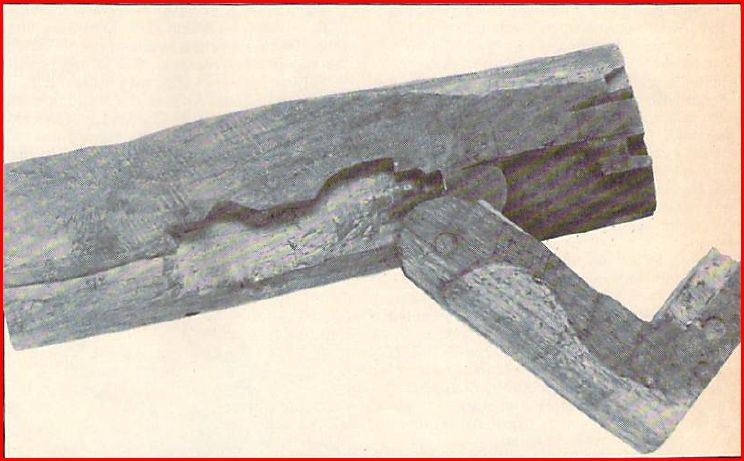

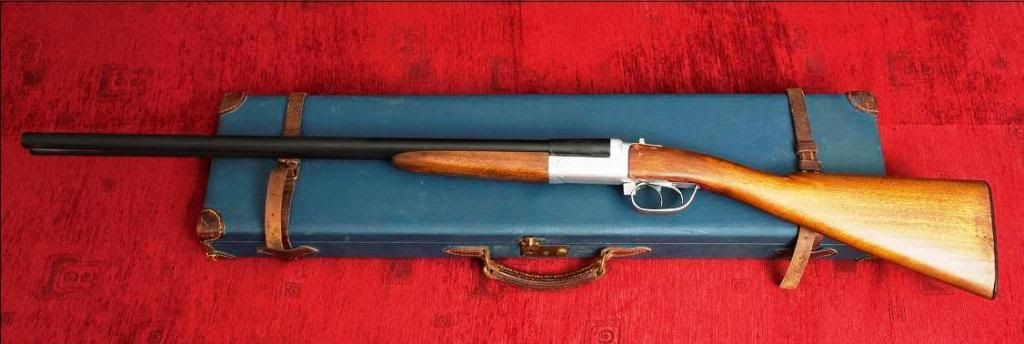

How it all starts- this is the wooden prototype that later became the Churchill Zenith. The photo was sent to me by the late colleague Geoffrey Boothroyd. This is the actual factory model made to test the barrel to action joint.  [/img] [/URL] This is the prototype I made using 3D printing that Obsessed with doubles found "crude". This is made of plastic, aluminum and cheap wood to test ergonomics. Technology does make some things easier. [img:left]http://  [/img]

|

|

|

|

|

Joined: Oct 2010

Posts: 969 Likes: 38

Sidelock

|

Sidelock

Joined: Oct 2010

Posts: 969 Likes: 38 |

Smallbore,

Over the years I have been in many gun factories and workshops and the only one where I saw foging take place was Fratelli Rizzini in Italy. Even then it was forging lumps on barrel stubs. Forging a whole action body would, and I am guessing, need a pretty heavy hammer forge and make huge vibrations and noise for the staff and neighbors. Which makers would have such large facilities to forge their own actions?

Offhand I would speculate that W.&C. Scott did, Greener, and perhaps others in Birmigham. The facilities of Holland on the North Circular road and Purdeys' in Paddington, I wonder how they would use a steam hammer there. But it has been a while since I was in London and maybe they have bigger places now.

With modern means, you can start from billets and EDM wire erode the shape pretty fast with minimal fuss, noise or fumes. I wonder if it is going that way.

Last edited by Shotgunlover; 12/17/13 07:29 PM.

|

|

|

|

|

Joined: Feb 2005

Posts: 7,438

Sidelock

|

Sidelock

Joined: Feb 2005

Posts: 7,438 |

Quote:

"Forging a whole action body would, and I am guessing, need a pretty heavy hammer forge and make huge vibrations and noise for the staff and neighbors. Which makers would have such large facilities to forge their own actions?"

Unrelated but perhaps useful information. Years ago when I worked for International Harvester in Ft Wayne, on a clear night you could hear their drop forge in operation. I lived over 10 miles from the drop forge location. Yes it was that loud.

Last edited by italiansxs; 12/17/13 07:41 PM.

The 2nd Amendment IS an unalienable right.

|

|

|

|

|

Joined: Dec 2001

Posts: 3,964 Likes: 89

Sidelock

|

OP

Sidelock

Joined: Dec 2001

Posts: 3,964 Likes: 89 |

But couldn't a usable forging be made using a heavy trip hammer and multiple heatings? Seems to me some of the old time blacksmiths could have accomplished it on anvil. Rough, yes but a usable beginning for an action filer.

When an old man dies a library burns to the ground. (Old African proverb)

|

|

|

|

|

Joined: Oct 2010

Posts: 969 Likes: 38

Sidelock

|

Sidelock

Joined: Oct 2010

Posts: 969 Likes: 38 |

Actually Smallbore in his thread re springs shows some informative pics of EDM and CAM technology used by Purdeys. It looks like they profile the actions from forged pieces using EDM wire eroders.

Those forged pieces do not resemble the action forgings I worked with in the past, which were much closer in shape to the finished article. These things are HUGE!

It is worth a look, definitely.

|

|

|

|

|