I've started prepping my first set of practice barrels I picked up for $10. A few questions about prepping and polishing:

There are tiny rust pits on the exterior. Should those be removed by wet sanding? I've started with 180 grit and the spots are much better. I'm wondering if I should drop down to 100 grit, or stay the course and just know that it takes a long time to wear that stuff down. At what point would someone use a draw file?

I have been using 6" strokes. Is that too long? Should I make long strokes while using the heavier grit, or is it okay to focus more aggressively on the small spotted places. Does it matter? I was going to make sure to use consistent strokes when I got to the finer polishing stages.

Do I need to cross sand when I move up in grit? Larry Potter did on a rifle barrel, but that was easy for him since there wasn't a rib in the way?

Thanks for the responses!

A few points.

First, about the initial prep for barrels in rough shape. You can either file of sand the pits, depending on depth and location. In areas where the barrel is thicker and pits are larger, I opt for the file first, switching to sandpaper when the pit is almost gone. If the barrel is really pitted, I'll place them in a shallow tray with water covering them so the water action removes the residue with each stroke, it's easier to see progress that way and saves on sandpaper.

Initial stroke length is not so important, it becomes more so in the last two grits, the last one especially, as even 320 can leave swirls if the strokes are not straight. Cross strokes are used in the coarser grits, they do aid in pit removal.

Focus on the spotted areas is ok, but if you cross sand make sure you blend the areas in before you move up in grit. Never move up until the mark is gone.

On really rough areas I sometime start with 80 grit, (spot areas) and in extreme cases, 46. At that grit, the file is an option, make sure to finish with a fine one and when switching to paper, remove all file marks with the first grit.

Thank you, Ken. Exactly the info I was hoping to receive. Very helpful.

One more question - I don't think this barrel will need a file, but if it did what would you recommend to use? My tool collection is not real heavy in the file department.

Kens advice is good. I usually start with 220 Wet or dry on a rough barrel, UNLESS it needs filing, Then I go to 420 and finish up with Scotchpad medium type stuff. I dont like to go finer as I think it makes the finish too bright and not as they were when orignally finished.

Thank you, Ken. Exactly the info I was hoping to receive. Very helpful.

One more question - I don't think this barrel will need a file, but if it did what would you recommend to use? My tool collection is not real heavy in the file department.

Well, most of mine, and I have dozens, were picked up for pennies at garage sales and flea markets. For the most basic needs, you can get by with an inexpensive needle file set. You'll find that a larger selection comes in handy, even the larger "Bastard" files. Mostly, you'll end up using the medium and fine ones. Here's a couple of file tips: Don't store them piled together so they bang against one another when you rummage through your collection. I use an old silverware set box to keep mine organized. Second, get a piece of copper pipe, split one end and flare it out like a spatula. Use that to clean you files, it works much better than a wire file card.

If you intend to use a file on barrels it is a must that you chalk it well first otherwise it will pick up filings that clog the file and leave score lines in the metal, and the softer the metal the deeper the scoring will be. Better still fix with adhesive wet and dry paper of various grades to lengths of hard wood this not prone to clogging and leaves a far better finish.

By changing direction of the polishing,you can tell much better when to go to the next finer grit, but always finish parallel to the barrel.I like to finish with worn 320 grit.Don't be afraid to work "buggers"

with a swiss file, but "fair it in" to the adjacent surfaces.You can use a file card to clean the file quickly, but the advice to use the copper(although I use a cartridge case with the neck flatened)to clean out the "pins"is very good. It is heart breaking to almost finish and scratch the surface,chalking is also good advice.

Mike

Chalk the barrel or the file - or both?

Chalk the file.

How are you going to card the barrels?

I'm in the process of doing nine sets right now, a mix of modern steel, Damascus, and Twist.

Steel wool was my plan, although I have a high speed bench grinder.

If you use a motorized wheel to card, typically it would be at slow speed with very fine wires. Too fast and/or too coarse will remove too much of the oxide that you worked so hard to achieve. Better to stick with fine steel wool in the beginning, and carding under slowly running water is easier and lets you see any spots you may have missed more easily. Use gloves or you will need to degrease again.

Very smart of you to learn and practice on an old junk set of barrels. You can practice on the same set as many times as it takes to get the hang of it. You might also want to try a couple other old junk single shot barrels before moving on to the big time, and then you will learn that sometimes you need to adjust your techniques or solutions or rusting times for different steels. Too many guys start out with grandpa's Parker or L. C. Smith and ruin a nice old gun with real potential. Sometimes you may be better off leaving remnants of deeper pitting rather than trying to get it all and removing lettering, engraving, or excessively thinning the barrel and leaving dished out areas. When you learn to do a good job, you will understand why the pros charge so much to rust blue or brown a set of barrels. The materials don't cost a lot, but it is time consuming and labor intensive. Good luck.

Steel wool was my plan, although I have a high speed bench grinder.

Make sure to degrease your steel wool. I keep several pads soaking in a jar of acetone at all times. If you get to the point when you're doing this more frequently, I agree that mounting a wire wheel to a grinder is not a good idea. I use a Brownell's four row fine wheel which I mounted on a spindle made from a threaded bolt. Initially, I mounted it on my large drill press, turning at a fairly slow speed. Now, I use it in my variable-speed corded drill. I made a simple jig to hold the barrels. I find it easier to control the speed, angle, and pressure on the barrels that way. It also enables me to reverse the direction often to keep the wires from bending. I also lightly dress the sides of the wheel with a file card after each set to keep the wires straight.

To card areas like the rib-barrel joint I use the steel wool and a shaped craft stick to get into the joint, just be careful you don't overdo it and leave streaks. Don't forget to wear gloves, but I'm sure you know that.

Good luck, prep and degreasing are the key

What rusting solution do you plan to use? My very first attempt 25 years ago was rebluing a rusty old H&R 922 revolver. I hand polished it down to a near mirror finish ending with crocus cloth. I used a home brew formula from Angiers, the 1873 Ordnance Formula, as I recall. I should have cut the solution more with distilled water, or shortened my rusting times, because I ended up with a pleasing blue-black matte finish that was not what I really wanted... a little too much "bite". I learned a lot from that experience, and I'm still learning.

Shop I got the barrel from has a bottle of Pilkingtons. I bought the barrels out of their trash can and decided to see how the cleaning up went before I jumped in with the bottle of solution.

Thanks for the tips. I'm sure I'll be back with more questions on this soon enough.

I never wear gloves, I learned to make plugs for ends of the barrels and handle them by the plugs both when applying the solution and carding;but not when boiling them.I was not able to find a fine enough wire wheel to satisfy me, even runing it on an arbor driven by different size pulleys to slow it way down.My German gunsmith friend taught me how to do it and he used a wheel with wire that was hair "fine".I just went to 00 steel wool(degreased with acetone also).For what ever it's worth, Walter taught me to apply the solution with 0000 steel wool( degreased with acetone).It was his theory that the steel wool would cut through any oil droplets that might be in the air and fall on the work.He would put a little solution in a bottle cap and wet the steel wool from it,instead of taking a chance of contaminating the whole bottle with steel wool.We use a small piece of wool and squeeze it out a little so it won't be too wet,resulting in runs.

Mike

....I have been using 6" strokes. Is that too long? Should I make long strokes while using the heavier grit, or is it okay to focus more aggressively on the small spotted places. Does it matter?....

I think set up good lighting, particularly to see the consistency of the reflection off the area you're working on. Assuming you have the material thickness to work with, you may remove pits, but if you leave a divot or contour change that doesn't belong, it might not look right even if you go through a good sequence with the finer grits. Best of luck with it.

I use Liberon brand oil free steel wool, 0000, for carding. Works a treat and doesn't require de-oiling like hardware store brand wool. On the downside it costs more (but a package of it lasts a loooong time).

Can I say that over many years of bluing and browning barrels I have found that the people who did this for a living devised methods of doing things to make their life at work easier, and not wanting to reinvent the wheel myself I copied there methods so here are a couple that will help anyone be more successful rust bluing.

Plug the barrels, clean out the extractor holes to remove any oil, prevent the browning solution from reaching places where you do not want it to go i.e. the breach end of the barrels and in some cases the barrel flats. Degrease the barrels properly.

For plugging the barrels use laboratory rubber bungs because they are not affected by heat, boiling water, or the rusting solution. But if you just plug the barrels there is a chance that the pressure build up inside the bores when in the boiling water could pop the bungs and allow water to enter the bores, and if there is any oil in them contaminate the water.

So to prevent this their solution which also cured another problem which is holding and positioning the hot barrels for carding.

Each rubber bung had a hole through the centre being a tight fit on an Iron rod which was threaded at each end. This rod would travel the length of the bore and extend past each bung by about four inches, a metal washer was placed next to the bungs with a nut at each to keep the bungs in place also compressing the rubber preventing water seeping past the rods. (1/4 inch threaded rod works just as well and can be purchased in standard lengths) fitted on the ends of each rod is a wooden handle to hold the hot barrels without burning your hands. To complete things a length adjustable wooden stand with six inch uprights at each was used to lay the Iron rods on that extended from the barrels so they could card the barrels top and bottom, also in the uprights a narrow slot was cut so the rods could drop into to enable the barrel sides to be worked on as well.

To keep the rusting solution off areas they used a Shellac/Pitch/Alcohol based mixture brushed on which was fast drying boiling water resistant and easy to remove.

Degreasing was done with a caustic mixture rather than solvents possibly because the action was to saponify the oils and greases, this usually consisted of a strong solution of Sodium Hydroxide (this is extremely caustic and will cause chemical burns) a less caustic solution is made from Sodium Carbonate (you may know this as ‘washing soda’) each works well if you submerse the barrels in the solution.

And just my personal preference I always card with steel wool I have tried using a fine wire wheel but it sometimes produces a patchy finish.

Finally the water you must use Distilled, Demineralised, Rainwater. Rainwater was preferred here possibly because it was free and we do have rather a lot of rain over here in Brit land.

Try to settle on a couple of rusting solutions and practice with them my personal preference is one solution with Mercuric Chloride and one without, the Mercuric chloride does speed up rusting especially if you have a dry atmosphere. Though better still by the book the reprint is not costly ‘Firearm Bluing and Browning by R.H. Angier’ and formulate your own personal mixture for the atmosphere where you live.

Modern, water-based polyurethane is what I use to coat the bores and the other areas I want to keep free of solution.

If using a wheel, since going fairly slow is key, that's where the variable-speed drill works well.

Now, THIS is a useful thread!

SRH

I just use tap water,never had trouble.Walter used tap water, and German water is very hard, it didn't cause problems.Water is used only to kill the rust,turn it black, and the work is well carded afterward.Also I don't mask off areas, I just keep the solution off unwanted areas as best I can during the bluing.Afterward, I polish the flats,the sides and rear of the under lugs,rear of the barrels and front of the muzzle with worn 320 grit abrasive.I don't worry about getting water into the barrels,I just tip them to the rear to pour it out and after boiling for 15 min. the barrels are hot enough to dry instantly.If I'm not going to apply another coat right away, I don't card until right before I am.Never let the work go over night rusting, always boil it and card the next day.

Mike

A good source of mineral free water is air conditioner condensate. I collect it in the summer months in plastic jugs.

There's really no need to plug or urethane the barrels if you're just doing bluing. It's necessary when you're etching Damascus, Twist, or Laminated barrels.

Dehumidifer water works as well. I suspect that water from one of those filter pitchers would work also.

What do you use to remove the water based polyurethane from the bores after the job is done Ken? I've been using shellac which is fairly easily removable with denatured alcohol. I've also used rubber plugs with pieces of brake line tubing bent upwards at 90 degrees to vent any pressure above the boiling tank surface. I like Damascus's idea of using a long piece of all-thread to secure the stoppers, but my boiling tank would not be long enough for a few inches of all-thread sticking out of the ends of 30" tubes. Maybe a piece of all-thread just a bit longer than the barrels with a couple pieces of flat stock for hooks/handles, held on by the same nuts that secure the plugs...

Has anyone tried using steam rather than boiling tanks? I saw one set-up on the internet that used a vertical 3" PVC pipe that was glued into a toilet bowl flange, which was screwed onto the perforated lid of a pot. Barrels were suspended vertically in the upright PVC pipe once there was a good head of steam. Said advantages were much shorter rust conversion times due to not having to boil a much larger tank of water. No need for a pipe or multiple burners. Less fuel consumption, and the guy claimed that most of the original gun manufacturers used steam.

I agree that this is a great thread, and there are always new techniques to learn from the experiences of others.

I like Damascus's idea of using a long piece of all-thread to secure the stoppers, but my boiling tank would not be long enough for a few inches of all-thread sticking out of the ends of 30" tubes. Maybe a piece of all-thread just a bit longer than the barrels with a couple pieces of flat stock for hooks/handles, held on by the same nuts that secure the plugs...

No need for a pipe or multiple burners. Less fuel consumption, and the guy claimed that most of the original gun manufacturers used steam.

I agree that this is a great thread, and there are always new techniques to learn from the experiences of others.

Keith:

I do quite a few high gloss rust blue barrel jobs along with many regular finish jobs and cleanliness is utmost in my operation. Both my rusting tanks are 42" long welded steel. I installed electric heating elements in both ends which boil very even and consistent without the mess and uneven boiling associated with gas burners. I have used both of these boiling tanks for years without any problems.

I have used rod stock with fender washers and machined plugs, of various materials, that I made for different barrel sets that work quite satisfactory when I need them and choose to use them.

Tony Treadwell used my idea and fashioned his boiling tanks like mine and he was very pleased. PM me if you have any questions, good luck.

Best Regards,

What do you use to remove the water based polyurethane from the bores after the job is done Ken? I've been using shellac which is fairly easily removable with denatured alcohol. I've also used rubber plugs with pieces of brake line tubing bent upwards at 90 degrees to vent any pressure above the boiling tank surface. I like Damascus's idea of using a long piece of all-thread to secure the stoppers, but my boiling tank would not be long enough for a few inches of all-thread sticking out of the ends of 30" tubes. Maybe a piece of all-thread just a bit longer than the barrels with a couple pieces of flat stock for hooks/handles, held on by the same nuts that secure the plugs...

Has anyone tried using steam rather than boiling tanks? I saw one set-up on the internet that used a vertical 3" PVC pipe that was glued into a toilet bowl flange, which was screwed onto the perforated lid of a pot. Barrels were suspended vertically in the upright PVC pipe once there was a good head of steam. Said advantages were much shorter rust conversion times due to not having to boil a much larger tank of water. No need for a pipe or multiple burners. Less fuel consumption, and the guy claimed that most of the original gun manufacturers used steam.

I agree that this is a great thread, and there are always new techniques to learn from the experiences of others.

Keith,

I use a long steel rod with the end shaped to hold piece of a green scrubby pad. I use that in my electric drill. The pad is cut so that when the two sides are folded in (like a spiral) they fit snug while the rod is spinning. I soak the pad in acetone, and use a hull as a bushing for the chamber. Besides removing the poly it does a real good job of polishing the barrels. I work from chamber to muzzle, and make sure the pad never comes completely out of the muzzle. Someone on this board mentioned using a green pad this way, that's where I got the idea.

What I've read about steam is that you've also got to be able to use dry heat as a part of the process, as constant steam will cause droplets that cause spotting. The Parker Process mentions "wet" and "dry" heat. My drying cabinet (old metal wardrobe type cabinet) uses a large crock-pot full of hot water in the bottom, set on high. I've three rows of rods mounted at the top, the barrels hang vertically on rod hangers. There's enough room for a dozen barrels. It's warm and muggy like an Iowa summer in there. Four-hour rust cycles are no problem.

My boiling tank is made from a cylinder, I use it vertically on a high-output natural gas wok burner. My other tanks are mostly made from 3 1/2" PVC, used vertically as well. They're for Ferric Chloride, neutralization (Baking Soda), Logwood, (I pour boiling logwood in, then soak the barrels). For the Ferrous Sulphate soak I use an open tray, made from a section of plastic rain gutter..

Here's a question of my own. It's about ribs with minor leaks. Whenever I see evidence of a rib leak I use the "two hole" method so I can flush and blow out the liquids with compressed air. After completion, do you put anything into the rib void? I've read that some use shellac. I've got a cutting edge rust inhibitor, I'm considering blowing that into the rib and then following up with shellac to prevent corrosion.

Doug, I've admired the level of gloss you are able to achieve with the rust bluing process. Some say it can't be done, so why polish beyond 320 grit? But you and CJO and a couple other guys manage to get a beautiful gloss. I do much better than my first attempts where I was using a homebrew solution with too much bite and overly long rusting cycles, but you can bet I'll pick your brain the next time I do some barrels. I haven't done any rust bluing for a couple years, and I'm hoping to do a few sets of shotgun barrels, a Wickliffe 76 .45-70 falling block barreled action, and a .32-20 revolver this spring if time permits. I'm concerned about the Wickliffe because many of the original factory hot blued jobs have plum colored receivers. I made my boiling tank out of 12 or 14 ga. stainless with welded ends, and I made it only 34" long figuring that the longest barrels I'd likely do would maybe be 32". I use a home built pipe burner that uses natural gas and works pretty well, but I like your idea with the electric heating elements. Do you recall the wattage of them?

I'm still intrigued by the steam process for rust conversion. The set-up I described earlier looked a bit top heavy and prone to tipping over, but the guy did caution that the steam chamber had to be very hot to avoid condensation and subsequent spotting on the barrels. I was also wondering about the PVC pipe becoming soft from the heat too, because I've bent 4" schedule 40 after warming it with a heat gun. I haven't had any problems with boiling my parts, but am always open to something that might work better. That's why I was hoping maybe someone here had actually tried it.

Ken, I've only had a couple sets of double barrels that gave off a small stream of bubbles indicating a small rib leak. Both already had a small weep hole drilled in the short rib between the lump and forearm loop, presumably at the factory. I flushed them repeatedly with baking soda solution after bluing, and followed with isopropyl alcohol in a syringe to mix with any water left between the barrels and ribs. Alcohol and water mixes great... just like with Bourbon and water! Then I put them in a large solar oven (whatever vehicle I wasn't driving with the windows rolled up!) for a few days to let the heat drive out any remaining moisture. Then I sprayed into the weep hole with Starret spray lube.

Several years ago, I bought some junk double barrels to practice rib jointing and soldering,and when I removed the ribs on a "nice" set of Baker Damascus barrels, the area in between was somewhat rusty and filled with debris from manufacture, but there was no evidence that corrosion had been actively eating its' way through the barrels. I think we may worry too much about what goes on in there because the entire area was certainly tinned prior to soldering. Yet I've read where guys say they have found barrels pitted clear through between the tubes. So was this corrosion from the bore outward or vice-versa? I guess it's possible we might have to re-do a set of barrels if we ever damage them, so something like shellac might be less likely to give us fits years later. Before anyone gets upset at me destroying a "nice" set of Baker Damascus, let me say that these barrels were almost perfect except for a small area about 8-9" ahead of the breech where something severely rusted the left barrel and top rib. The rust had actually eaten clear through the barrel. Rabbit blood? Battery acid? Who knows?

I would just like to add a few things that my post did not make very clear. Firstly about the rust bluing process the people who were undertaking this where doing it to earn a wage so their outlook was more along the lines of speed and only wanting do the work once. So more often than not they were using express rust bluing formulas each set of barrels took approximately half an hour from start of bluing to finish, though they did sometimes use formulas not containing mercury and only very low levels of acid to give that blue with a mirror type gloss though taking more time to complete and costing the customer more. Now express formulas had vast amounts of Mercuric Chloride in their makeup so it was inevitable that some would find its way in to the boiling tanks, now Mercuric Chloride did not get the name Corrosive Sublimate for nothing and as they say prevention is far better than a cure because if you do get it in a gun bore it can cause rusting days and sometimes weeks after the work was completed. The bores of the barrels where plugged to keep this out as well as any residual oil in, and if you are processing may be dozen barrels a day the boiling water was probably a strong chemical soup by the days end. Also the pitch in the shellac was there as an aid to its removal no black all traces of it is removed and why clean the bore if there is no need to, so keep as much foreign matter out as possible.

Just a couple of things now rust under the ribs in the barrels initial manufacture especially the top makers here still use the traditional Colophony (Tree Resin) as a flux the reason is twofold firstly to aid the solder to flow at lower temperatures and second it would cover a considerable amount of the bare metal surfaces under the barrels ribs slowing down under rib rusting. And finally after bluing was complete the barrels were put in to a form of dewatering oil based on Lanolin if while re-bluing there where noticeable air bubbles emanating from a barrels ribs these barrels where placed in a hot cupboard for a time, then placed in to a cold dewatering tank and as they cooled down the oil would be drawn under the ribs. The barrels were removed from the dewatering tank and left to drip dry then given a polish with a leather pad improving the surface gloss.

From the photographs posted by PA24(Doug in Utah) in the past and now, it is my opinion that he has learned that polishing is the key to the success of blacking barrel to get the results that the great barrel blackers of the UK get and have gotten through the years. I do not know what blacking solution that he uses but it is beautiful and works very good and his boiler set up is excellent as well.

It is good to have a topic of learning and advice giving on this BBS as that is the way it was in the days of it's origin. The excellent barrel blackers are not keen on giving out their formulas or techniques. I remember back 13 years ago I was asked to leave the workshop of the famous color case hardening company in Price Street, as the owner was and had reason to be protective of his processes---the best of the best of the world. Some of you will recall the author of "Birmingham Gunmakers" fame, Doug Tate was also asked to leave this shop. I was sadden to see this grand old gentlemen who knew all the secrets of blacking die last year. But he passed the secrets and mysteries of the trade to his sons. Barrel blackers are the same.

From my observations in the UK and USA, no single blacking or browning formula works the same way throughout the regions of these countries due likely to atmospheric, ambient temperatures, shop conditions and so forth--thereforth you do not find a single formula being used by all the trade. However, one issue paramount and singular consistent of the techniques of the very BEST blackers is: POLISHING; and polishing means hours of hand work with emery cloth using grits well beyond 320--or at least "worn out" emery cloth strips.

I believe that it is the degree and amount of hand polishing that both Doug of Utah and I use to arrive at barrel gloss that is almost identical--with likely very different ambient conditions and blacking formula.

Desmond Mills, the highly respected English gunmaker/gunsmith late of Purdey's and Churchills; and now retired or mostly retired, has this to say about polishing of barrels prior to blacking: "...because the sharp corners of the ribs, the breech and muzzle ends of the should be preserved, THIS means careful handwork and the FINEST grades of emery cloth should be used. The exterior of the barrels CAN be wheel polished and MUST be so highly polished that they look like they are chrome plated. THIS forms the foundation and quality and appearance of the barrel finish. .....Once the barrels are PERFECTLY polished and next and absolutely essential is degreasing......"

I have avoided using the soft cotton wheel (I plan to give it a try sometime) as mentioned by Des, but nevertheless I attain the chrome plated appearance with finest grades of emery cloth, with the final polishing using "worn-out" emery cloth strips of the finest grade grit I have in my shop. The formula I use is the Swiss formula from Algiers book, as it works well in a moderate to high humidity region--you just need to adjust the amount of the 100% alcohol used for your ambient conditions. The alcohol needs to be pure and near 100%--I use the 96% grain alcohol one can procure at a liquor store.

It should be evident by what Des has written in his book above that he is sharing with us what he has seen done by the best of the best barrel blackers who did Purdey and other best quality gunmakers work in his then 30 years at the bench when he wrote his book in 1985--thirty years ago.

I hope this above helps some of you.

I have seen plenty of gloss barrel blacking done in the UK for the trade and it looks great until you place in in the light of day and see all the work that needs to be done by proper polishing that is showing under the blacking grinning back at you as Jack Rowe is fond of saying. Tradesmen cannot spend the polishing time it takes to make a barrel perfect, if they are being paid for a quick ordinary job.

I have seen little (almost none) high gloss work in the USA, until Doug showed us his work. Is it possible that barrel blackers here do not know what they do not know?

Kindest Regards;

Bv

Just a couple comments.Years ago, the barrels(german)were completly tinned before ribs were attached, to prevent rust under them.Then this practice went away, likely due to cost of cleaning the excess off.If a leak indicates a rib comming loose, the bluing should stop until the rib is repaired. With regard to applying a rust preventing oil under the ribs, after bluing;I watched Walter Grass "worry" a piece of chord through a threaded hole in a bottom rib(using scribe and compressed air)and then soak the chord in Ballistol.With regard to using steam,I had a rifle barrel start turning black during rusting,because of temperature and humidity during an Alabama summertime.

Mike

I use distilled water from the drugstore--it's only like $3/ gallon, and my smaller bluing tank only uses 3-4 gallons. No big deal, if we're talking about a few hundred bucks for the bluing job. If you see oil drops coming to the surface of the boiling tank, a half piece of paper towel laid onto the water surface, and quickly picked up, BEFORE you pull the barrels out will ensure the oil will not contaminate the steel, and make a camo job out of it.

Keith,

I haven't used steam, but I did once use boiling water from a tea kettle poured over and down the barrel of a rifle, after using Laurel Mtn browning solution on it. Nice matte blue.

SRH

From the photographs posted by PA24(Doug in Utah) in the past and now, it is my opinion that he has learned that polishing is the key to the success of blacking barrel to get the results that the great barrel blackers of the UK get and have gotten through the years. I do not know what blacking solution that he uses but it is beautiful and works very good and his boiler set up is excellent as well.

It is good to have a topic of learning and advice giving on this BBS as that is the way it was in the days of it's origin. The excellent barrel blackers are not keen on giving out their formulas or techniques. But he passed the secrets and mysteries of the trade to his sons. Barrel blackers are the same.

From my observations in the UK and USA, no single blacking or browning formula works the same way throughout the regions of these countries due likely to atmospheric, ambient temperatures, shop conditions and so forth--thereforth you do not find a single formula being used by all the trade. However, one issue paramount and singular consistent of the techniques of the very BEST blackers is: POLISHING; and polishing means hours of hand work with emery cloth using grits well beyond 320--or at least "worn out" emery cloth strips.

I believe that it is the degree and amount of hand polishing that both Doug of Utah and I use to arrive at barrel gloss that is almost identical--with likely very different ambient conditions and blacking formula.

I have seen plenty of gloss barrel blacking done in the UK for the trade and it looks great until you place in in the light of day and see all the work that needs to be done by proper polishing that is showing under the blacking grinning back at you as Jack Rowe is fond of saying. Tradesmen cannot spend the polishing time it takes to make a barrel perfect, if they are being paid for a quick ordinary job.

I have seen little (almost none) high gloss work in the USA, until Doug showed us his work. Is it possible that barrel blackers here do not know what they do not know?

Kindest Regards;

Bv

Bushveld and Keith,

Thank you for your kind words and compliments, appreciated. As Bushveld mentioned the key is in the hand polish work and most folks don't realize the hours and hours of hand work required to refinish a set of barrels the proper way.

If you hold your polished set of barrels in bright sunlight and see NO FLAWS, SHADOWS, GHOSTS whatsoever and the polishing is all unidirectional and as near perfect as you can make it, then you are ready to start rust blueing/blacking. You can adjust your polished finish in the white to be like chrome for high gloss or dull for a duller finish, as required or desired. Everybody uses different methods, but the end result must be as noted above. The polishing is key, just like painting a car, if it's ugly before you apply the paint, it is going to be ugly after the paint dries.

In my opinion the water purity is not as important as the polishing factor, most impurities boil off as you fire up your tanks anyway. The boiling water will soon become contaminated with rust blueing/blacking compounds as the number of passes increase. If you have the availability to collect rain water, it is about as good as it gets for boiling and is an easy souce of good water for this application.

If done properly, a good rust blue job will last for years and maintain it's luster with just a little care. I rust blue quite a few rifles as well with good results and I've included some pictures below to show that the level of polish can differ depending on the desired end result and how the different steel alloys will accept the rust blueing/blacking differently which gives you some really nice SUBTLE color contrasts. Hand polishing and detailing is the key, no power tools or buffers/wheels of any sort at any time...all hand work only in my opinion if you want nice results.

Best Regards to All,

Doug, I must say that your results speak for the quality of detail that you have reached. Prep work is just about the least glorious thing done in any job but often the most important part of the job. I also place a high value on working neatly and paying attention to the detail as you go. I understand the temptation to cut corners or skip steps if not "needed" to produce work at a price point or crank out work in high volume but quality like you produce can not be short changed.

Some of the reading I have done has stated that a lower gloss finish is desired in some of the vintage American makes. That was the reason I gleaned for only polishing to 320 grit. Now I'm trying to figure out how to create a surface with no visible imperfections at such a low sanding factor. Do you polish the barrels higher up in shine and then dull them back down with something? Does the etchant help with this on damascus barrels? There's a lot to learn. I know I can polish a piece of metal to a mirror finish, but I'm not sure that's going to produce the period appropriate finish desired on certain guns.

Or do I have it all wrong regarding the 320 grit?

On Steel barrels, (rather than pattern-welded ones) you can certainly go finer than 320, since you're not concerned with pattern contrast. I sometimes go to 500. Here's a set of Armas Erbi Sidelock barrels that have had three cycles, with another two or three to go. These were polished to 400, but I could have easily gone to 500 on them. You can still see light sanding marks if you look closely, but they will be gone (to the naked eye) by the time all the cycles are completed. When sanding using the finer grits, some type of magnification is helpful. I use an "Optivisor, so I can see the progress.

I haven't tried it yet. but I'm probably going to experiment with a Vaporizer in my rusting cabinet. Anyone tried this yet?

I live in the country & get my water from a natural spring. I very quickly found it was not suitable for the boiling tank in rust bluing. I made several attempts on a set of barrels & each time they would come out with a red tinge. I then went & picked up some "Drug Store" water & repeated the very same process with excellent results. Because mine won't work doesn't mean no-one elses will & because one person is able to use tap water likewise doesn't mean everyone can. It all Depends on what's in that source of water.

I have done one job using steam & it worked fine. A co-worker of mine had a large knife which had belonged to his father that originally had a blued blade that had worn off over the years. He asked me coud I blue it for him without taking the handles off. I told him I would try & see if I could. After rusting the blade I put a tea kettle on & turned the heat up enough to get a good steaming at the spout & simply held the blade in this until it turned a good color & carded. I of course had to repeat the process several times to get the desired results.

I do recall having read where many of the world's armories when rust bluing was still being used by them had steam Rooms where large numbers of barrels etc could be hung & steamed at once. Some of the larger commercial factories may well have done this as well. In fact this was what gave me the idea to try steam on that knife.

At the risk of seeming obvious to others, may ask a question about polishing? All I have ever done is new barrels that were not stamped with any lettering. How do you polish the lettered areas without washing out the lettering? I can understand polishing up to it very carefully, but do you just leave the areas between the letters and words alone? Or is there some way to polish those tiny areas without harming the roll stamping?

SRH

I live in the country & get my water from a natural spring. I very quickly found it was not suitable for the boiling tank in rust bluing. I made several attempts on a set of barrels & each time they would come out with a red tinge. I then went & picked up some "Drug Store" water & repeated the very same process with excellent results. Because mine won't work doesn't mean no-one elses will & because one person is able to use tap water likewise doesn't mean everyone can. It all Depends on what's in that source of water.

I have done one job using steam & it worked fine. A co-worker of mine had a large knife which had belonged to his father that originally had a blued blade that had worn off over the years. He asked me coud I blue it for him without taking the handles off. I told him I would try & see if I could. After rusting the blade I put a tea kettle on & turned the heat up enough to get a good steaming at the spout & simply held the blade in this until it turned a good color & carded. I of course had to repeat the process several times to get the desired results.

I do recall having read where many of the world's armories when rust bluing was still being used by them had steam Rooms where large numbers of barrels etc could be hung & steamed at once. Some of the larger commercial factories may well have done this as well. In fact this was what gave me the idea to try steam on that knife.

I find that interesting, as the most famous Lynchburg product requires iron-free water for it's distillation. Their Spring must be fed from a fairly shallow aquifer, which is iron-free. Probably why I've read they're (or were) having water shortage problems due to drought. What you said makes local well water unsuitable for whiskey.

Regards

Ken

Good question, Stan.

Ken those barrels are looking great. Trying to polish up a set of barrels makes the damascus work I've seen Bachelder and others put out even more amazing. The colors are obviously very nice. Consistency of the polish they achieve is a headscratcher to a noob such as myself.

At the risk of seeming obvious to others, may ask a question about polishing? All I have ever done is new barrels that were not stamped with any lettering. How do you polish the lettered areas without washing out the lettering? I can understand polishing up to it very carefully, but do you just leave the areas between the letters and words alone? Or is there some way to polish those tiny areas without harming the roll stamping?

SRH

Stan,

You pretty much have to stay off of the lettering except for a couple of final unidirectional passes with whatever grit you are finishing up with.

First I clean the lettering very good with a small stainless brush to clean out the letters, then detail it very carefully with a very small square of 600 grit using the eraser on a pencil as the sanding block for directional and pressure control.

Best Regards,

Doug, can we see a more complete gun pic of that reblued Rem. M-12?

Jay

Good question, Stan.

Ken those barrels are looking great. Trying to polish up a set of barrels makes the damascus work I've seen Bachelder and others put out even more amazing. The colors are obviously very nice. Consistency of the polish they achieve is a headscratcher to a noob such as myself.

For pattern-welded barrels it's not only the initial polishing before rusting, but the final polishing as well. That's where my current "learning curve" is. On previous sets everything would be excellent through the rusting and etching cycles, yet the final polishing to bring out the contrast and figure would be lacking. I'm finally getting to the point where it's happening, and I'm fairly comfortable with the process. In fact, all my barrels have not yet had the final lacquer put on them, and the temporary rust inhibitor as well as the lighting results in a slightly yellowish cast to the color. The black-white contrast will be much stronger once I'm done with them. My next step is to buy a couple of "Daylight" bulbs for my lighting fixture.

On the question of water, is it likely that different solutions react differently to different minerals?

Mike

Thank you, Doug. That helps.

SRH

I think that the water problem is from limestone minerals in the well water, which will leave a slight residue of calcium on the barrels when they dry after boiling. This can leave lines of calcine which will inhibit the next application of the acidic bluing solution, causing variations in the next coat. Put some of your water in a polished stainless pan, and boil it off. The chalky residue is calcium carbonate.

Some of the reading I have done has stated that a lower gloss finish is desired in some of the vintage American makes. That was the reason I gleaned for only polishing to 320 grit. Now I'm trying to figure out how to create a surface with no visible imperfections at such a low sanding factor. Do you polish the barrels higher up in shine and then dull them back down with something? Does the etchant help with this on damascus barrels? There's a lot to learn. I know I can polish a piece of metal to a mirror finish, but I'm not sure that's going to produce the period appropriate finish desired on certain guns.

Or do I have it all wrong regarding the 320 grit?

Jawjadawg:

**If you want the standard "American Field Grade" barrel blue finish, polish by hand to 400 grit.

**As you polish keep checking that you have removed all of the flaws/ghosts/dings/pits and other imperfections. Draw file and polish as necessary.

**As you card your barrels after each rusting application CHECK the color as it darkens. When the barrels reach the FIELD GRADE BLUE, as was typical with lower grade American Field Grade guns you merely STOP with your rusting passes,boilings and cardings.

**You will then have a re-blued set of barrels that should look like they did when they left the factory, if you did your homework on color and polished the barrels properly to the best of your ability.

Best Regards,

Thanks Doug! I have one that was my grandfather's and then my dad's. It's in pretty rough shape, nice to see one looking as good as this.

Jay

A couple things I keep handy at my work bench for barrel prep, prior to bluing. I buy schedule 40 PVC in various diameters, and cut it lengthwise to make two halves. I cut these about 11" long, so a sheet of sandpaper fits and just overhangs each end. Depending on the diameter of the barrel, I use an appropriate size piece with sandpaper inside, and work the barrel length in strokes a little over half the barrel length. Then turn the barrel around, and work the other half, overlapping the strokes.

For octagon barrels I have a piece of 1" thick aluminum bar stock, about 2" wide. It is also cut the same length, and I wrap sandpaper around it to work down the finish and prep for rust bluing.

Half octagon barrels I work both halves up to the transition, but when it comes to final polish, I finish the octagon first, and then do the round up to the octagon, so I remove any polishing marks on the octagon from running over on the round portion.

Ken;

About a mile & a half from where I live there used to be a small lake which was created by a dam across the same creek which flows by by house. The remains of the dam still stand, but the lake is now dry. Used to catch some nice fish out of it. it is owned by the family who once owned the distillery of which you spoke. Back around the 1920's before this family bought it, another family built the dam & created the lake for a Resort. A short distance below where the dam is are 7 springs all bubbling out of the ground in a very small area. The amazing thing about these springs is that each one of them has a different type of water. It has been many years since I actually went there, in fact the whole area is now strictly "Posted" with big "Keep Out" signs everywhere. In the past I have been there & seen the springs personally & in fact tasted the water from them & they are in fact not the same water. One of them is Sulphur. As the crow flies as they say I live about 6 miles from the famous Lynchburg spring from which Old #7 is made, so there is certainly no indication of what their water is based on what mine is.

Some of the reading I have done has stated that a lower gloss finish is desired in some of the vintage American makes. That was the reason I gleaned for only polishing to 320 grit. Now I'm trying to figure out how to create a surface with no visible imperfections at such a low sanding factor. Do you polish the barrels higher up in shine and then dull them back down with something? Does the etchant help with this on damascus barrels? There's a lot to learn. I know I can polish a piece of metal to a mirror finish, but I'm not sure that's going to produce the period appropriate finish desired on certain guns.

Or do I have it all wrong regarding the 320 grit?

Jawjadawg:

**If you want the standard "American Field Grade" barrel blue finish, polish by hand to 400 grit.

**As you polish keep checking that you have removed all of the flaws/ghosts/dings/pits and other imperfections. Draw file and polish as necessary.

**As you card your barrels after each rusting application CHECK the color as it darkens. When the barrels reach the FIELD GRADE BLUE, as was typical with lower grade American Field Grade guns you merely STOP with your rusting passes,boilings and cardings.

**You will then have a re-blued set of barrels that should look like they did when they left the factory, if you did your homework on color and polished the barrels properly to the best of your ability.

Best Regards,

Doug,

Did you do the case-coloring on that as well? It's a spectacular example of workmanship, something for a humble amateur to aspire to.

Ken

Did you do the case-coloring on that as well? It's a spectacular example of workmanship, something for a humble amateur to aspire to.

Ken

Ken,

Yes, that is my case color hardening, blueing and wood refinishing. Thank you very much sir.

I also scratch make original style Rocky Mountain Silver front sights for Marlin rifles that have missing original front sights when I refinish the entire gun.

Best Regards,

xs hedspace,

Walter's water had enough calcium that the pot he boiled his water for coffe in had a quater inch or more around the sides and it still didn't hurt the bluing.I'm sure that the carding removed any calcium left on the barrels, but I never saw any.My water here doesn't have a lot of calcium, but it does have other minerals.Maybe carding it well and applying the next coat with steel wool did the trick.Everybody just uses whatever works for them.

Mike

Doug,

Are you one of the guys posting over on the Case Coloring thread on the Marlin Collector's forum? That's a great thread.

Ken

That really is a great thread, Ken. Thanks for mentioning it. As I gather more info before trying my hand at it, this is another great source.

SRH

That really is a great thread, Ken. Thanks for mentioning it. As I gather more info before trying my hand at it, this is another great source.

SRH

The real thanks goes to Jawjadawg, he's given us all the opportunity to discuss all this fun stuff..

I'm having a problem with Mark Lee Express blue that perhaps one of you can help me with. I have been trying to blue a 1909 Colt revolver. The parts are rather highly polished and have been cleaned repeatedly with acetone as well as boiling with a degreaser. The problem is that I am having a difficult time getting some areas to rust. They get discolored after applying the blue, but don't really rust. In the past I have used the same blue and techniques on rifle parts and had no problem. Any ideas?

Thanks.

I'm having a problem with Mark Lee Express blue that perhaps one of you can help me with. I have been trying to blue a 1909 Colt revolver. The parts are rather highly polished and have been cleaned repeatedly with acetone as well as boiling with a degreaser. The problem is that I am having a difficult time getting some areas to rust. They get discolored after applying the blue, but don't really rust. In the past I have used the same blue and techniques on rifle parts and had no problem. Any ideas?

Thanks.

Most likely the alloy purity of the steel, probably has a high nickel content in certain areas..?...Hot blueing would be your alternative.....

I didn't realize that an old colt like that would have high nickel content, but it fits the symptoms as it is behaving almost like stainless steel.

Now, isn't this thread much more fun than one's that degenerate into "Pissing Contests"?

Not to say that pissing contest aren't fun, but are what Misfire's is for..

I didn't realize that an old colt like that would have high nickel content, but it fits the symptoms as it is behaving almost like stainless steel.

Yes, nickel steel was making big advances in the early 1900's as smokeless powder started to take over.

Best,

Thanks. Is it possible that the metal is too highly polished? For example, I'm getting pretty good coverage on the indented portions of the cylinder, but the rest of the area which was probably more highly polished is only rusting well in some areas.

Thanks. Is it possible that the metal is too highly polished? For example, I'm getting pretty good coverage on the indented portions of the cylinder, but the rest of the area which was probably more highly polished is only rusting well in some areas.

Yes, precisely.....you could bead blast it down somewhat, then polish back up to 320 or 400 grit and try it again...should work, but may still be uneven based on the nickel content...?...

Hot blue is a sure thing if you want a higher gloss. Some also hot blue stainless now days and do a pretty good job. Smith and Wesson offers several revolvers in stainless blue, they look nice.

Best,

There is a lot of good info here, but also some Really bad, wrong, backwards.

Arguing about the water is just plain foolish. In Oregon I ran it out of the tap. In Montana I buy distilled. Please wear a dust mask when you card, especially if your solution has mercury!

Here is a link to photos of my process. I won't answer questions, so please don't email. I hope some pictures help some neophytes… I've been rust bluing for almost 40 years. The sweat box was made as an experiment almost 30 years ago and never replaced.

http://finegunmaking.com/page60/page60.html

I hope this question is not out of line, but many of us are still learning. What is "really bad, wrong, backwards" info?

I hope this question is not out of line, but many of us are still learning. What is "really bad, wrong, backwards" info?

I think that qualifies as a "Hit & Run". SDH does beautiful work, but I think like many professionals, he's leery of giving up his secrets so it doesn't affect his business. Understandable, and is a continuation of a centuries old tradition.

The rest of us "muddle through" and learn from our mistakes. I, for one, have made many, despite reading everything I could find on the internet. I have redone virtually every one of the first dozen Damascus and Twist guns I started with. If I had been closer, I think I'd have taken Diggory's course, but it wasn't an option.

One thing I've learned, unless you're a dedicated Do-it-Yourself type or have a large collection, you're better off sending a couple of guns out.

Rust-bluing requires being meticulous and paying attention to detail. For pattern-welded ones you additionally have to be downright "Anal" as far as details.

Ken

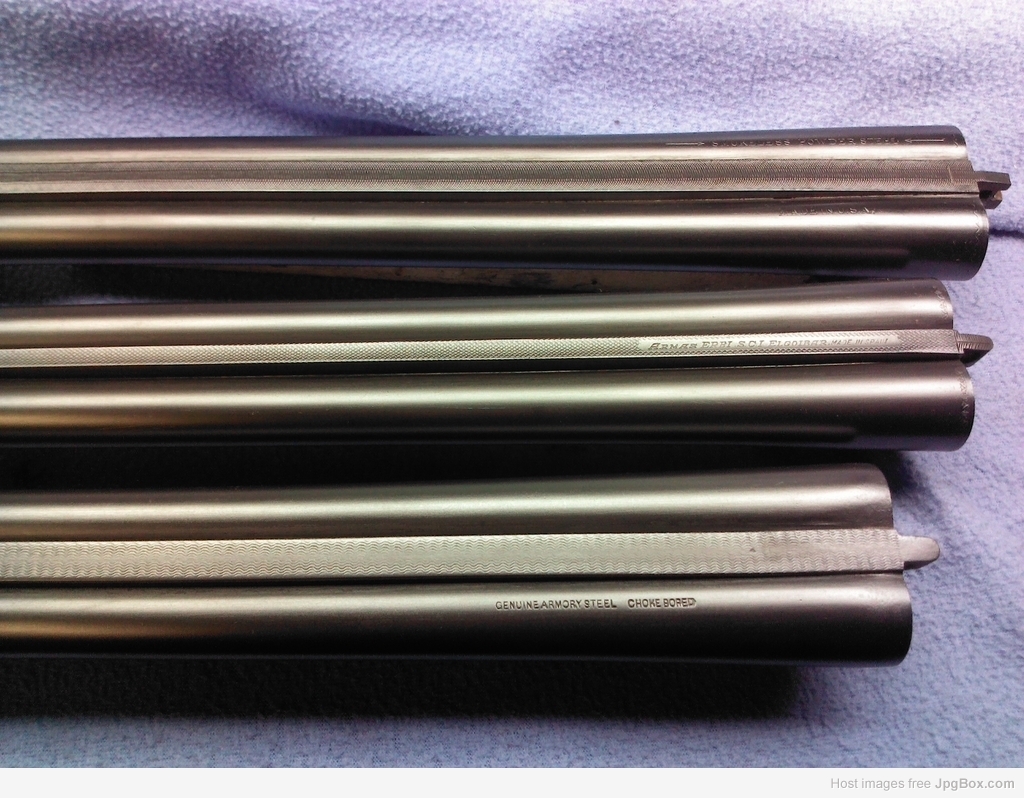

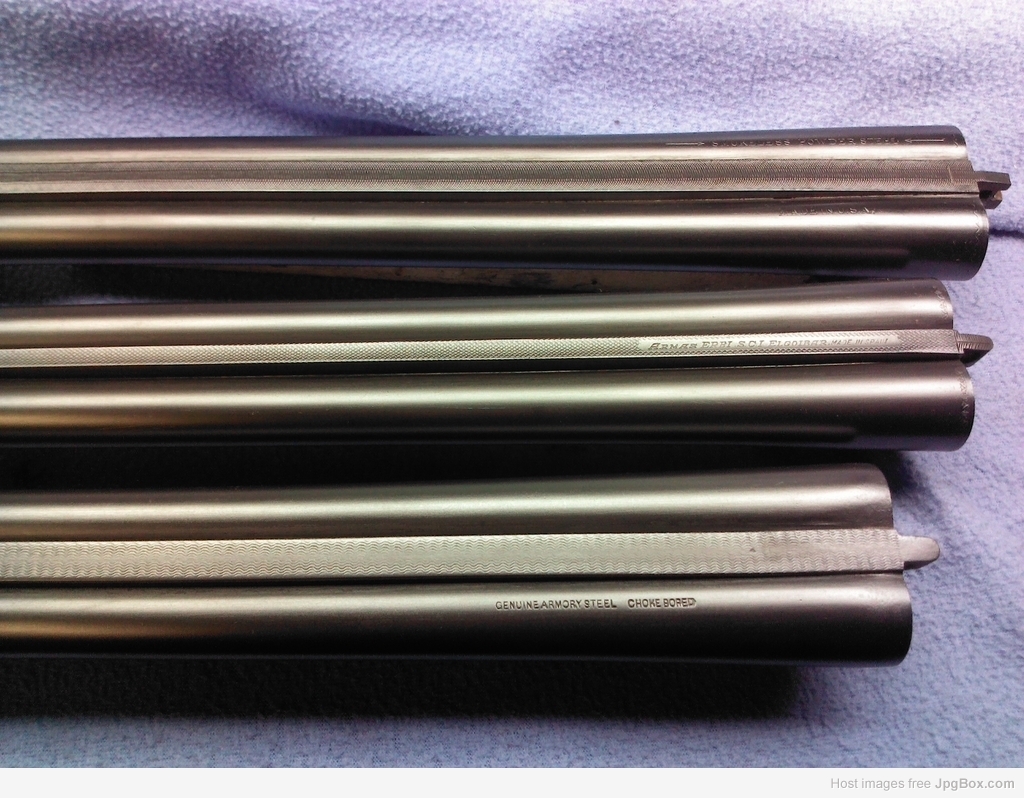

Here's three I just did the final card on. No oils or wax yet, but they have a very rich, deep black-slightly blue finish. I use an alcohol based Nitric Acid solution, the same one I'm using for my pattern-welded guns.

All are fairly humble guns. An Ithaca Flues on top, an Armas Erbi Sidelock in the middle, and a Crescent Hammergun on the bottom.

I don't post often, but this thread has been very interesting.

First, I would really wish the experts would provide their opinions on what is bad/wrong so those that are trying to learn cannot fall into some of the same traps. However, falling into those traps are sometimes the only real way to learn.

The other option is to take a class. I'm signed up to take my first summer NRA class and it is on slow rust bluing. I'm taking it at Trinidad, CO this June. I'm really looking forward to that class and this thread just make me wish June was hear already.

I hope this question is not out of line, but many of us are still learning. What is "really bad, wrong, backwards" info?

I think that qualifies as a "Hit & Run". SDH does beautiful work, but I think like many professionals, he's leery of giving up his secrets so it doesn't affect his business. Understandable, and is a continuation of a centuries old tradition.

Ken

If I point put the bad stuff I become a target for criticism and I don't have thick enough skin. Neither do I want to argue or open the door for more questions. There are literally hundreds to things to be learned from my pictures, I share them freely but folks still want more. Do you think I would be posting them if I was, "leery of giving up his secrets so it doesn't affect his business."? I only rust blue my own guns and there is nothing to effect my business.

Student project 6/15, third or fourth rusting before carding. Ruger actions are notoriously difficult.

The quarter-rib carding, nice and shiny, Lee's first bluing.

I'd be glad to give a seminar on rust bluing, and have included it in other classes but it is a whole lot cheaper to go to Trinidad. How many want to sign up for $1500 for five days? I'll teach you everything I know and you will do a professional job the first time, learn all the tricks and go home with a finely blued gun. My stockmaking student pay more than that and keep coming back.

I love to teach and I love to write, I just think it is fair to be compensated for it. It's your hobby, it's my business.

Best to all,

One of my favorite metal finish pics; a custom Marlin M-94 with rust blued barrel an mag tube, charcoal blued forend tip, nitre blued screws and mag. tube plug.

A palette of gun blues.

Bench-made front sight, same rifle. Rust blued barrel, nitre blued sight with 18kt gold bead.

Just a minor question I have been curious about. Why is "carding" called carding?

Just a minor question I have been curious about. Why is "carding" called carding?

It appears that the actual word "carding" comes from the textile industry in eary 1700's England. Carding was the term used to explain "separating various fibers" where wire brushes were used for this purpose.

As barrel browning became the norm during the same time frame, a very stiff brush was used to remove the brown oxides from freshly brown rusted barrels after they had sat out for 24 hours to rust and the word "carding" carried over to identify the use of the "stiff hard brush".

Soon it was learned that if they "boiled" the barrels with this iron oxide the barrels would turn black and blacking began.

Hope this helps.

Thanks Doug. I appreciate the answer. Carding rings a bell, now that you mention it, with the production of textiles. Funny how it moved to barrel blacking.

You also "card" files using a stiff wire brush to remove chips from the file teeth.

Carding was and still used in the wool industry.

Carding was and still used in the wool industry.

Funny. I always relate the term to showing my ID to prove my legal drinking age.

How many want to sign up for $1500 for five days?

Throw in morning and/or late afternoon hunting together and I'm there.

If a course provided barrel prep, polishing and dent raising and filing, not to a great depth as that might take the 5 days in itself and all the ins and outs of rust blueing it would be high on my list to attend.

My Dad was an antique dealer back home in Somerset, ..I remember he had a woold carding machine that involved a crank n several short stiff wire wide wire brushes...though we had no wool to test its worth, it was marked as a wool carding machine

franc

Here's my "Carding Bench" set-up. It's pretty basic, yet contains what I consider the minimum as far as tools and equipment. Even though they say that a picture is worth a thousand words, I'll provide an explanation for some of the items. So, instead of a "thousand words" perhaps people can learn a "thousand things" and avoid some of the mistakes that I initially made.

Everything above the bench is self-explanatory. Solutions, both full and diluted strength, as well as the drawers holding the various abrasives seen on the bench.

Left top, respirator and gloves. Optivisor at the top middle. Far left are my barrel holders, dowels in blocks that then fit into the notches of the flat holders. It divides the work into four parts. Far right are the carding wheels, a four-row on the corded drill, a one row on the small cordless one. I prefer to use the one row on ribs and tight areas, it's easier to see the tips hitting the metal, and it eliminated the temptation to "bear down" with the four-row wheel.

Specific abrasives in the middle. Used after the power carding. Green pad is only used in initial barrel prep, it's too coarse for further use. Next to it is a fine Scotchbrite (purple) pad. It has only very limited use, using only small pieces of it on specific small spots. It's best use is the final burnishing pad right before the first rust. Next to that is 000 synthetic (grey) steel wool. I use small pieces of it in the forceps to work on small areas, usually on pattern-welded barrels.

Lastly, we have 0000 degreased steel wool. This is what I use in conjunction with the shaped craft sticks for the small areas. Especially along the top rib. Strokes are very short, so as not to leave streaks.

The bottom of the bench shows what I use for application. A pair of forceps I clamp a sponge into. The sponge is squeezed well, for an even application. I use a Q-tip for the top rib joint, so there's not an excess of solution in the joint. Immediately after application, I use the heat gun to dry the barrels in order that there are no runs or streaks. The syringe is there to remind people to have one if flushing the ribs is necessary. An air compressor is the preferred method. The barrels are then put on a hanger and hung in the rusting cabinet. Lastly, I then use the file card to lightly dress the sides of the four-row wheel back to straight, so I'm ready for the next barrel.

This is pretty much what you need, but you could certainly hand card if only doing a few barrels.

Regards

Ken

So, instead of a "thousand words" perhaps people can learn a "thousand things" and avoid some of the mistakes that I initially made.

Regards

Ken

Good job Ken, thanks for posting your bench details and picture. After 50 years plus of rust bluing guns, albeit part time, I am slowly getting a handle on it. Still haven't figured out how to keep my fingers from cracking, gloves or no gloves, but I polish and card everything by hand, so no wheels, mills or laborers of any kind.

I finished up these 16 gauge Sterlingworth barrels yesterday for a member here.

Best,

Doug, those are some nice looking barrels. When you ship them back to the member, will you use some 3" PVC pipe to mail them or will you throw them into a cardboard mailing tube?

Doug, those are some nice looking barrels. When you ship them back to the member, will you use some 3" PVC pipe to mail them or will you throw them into a cardboard mailing tube?

I bet that member got "the lecture" from Doug about proper shipping of barrels just like I did last year when he did my Sarriugarte barrels.

I got the same lecture again from Doug when I sent my Fox and my Remington stock to him for repair. I wouldn't trust my barrels or stocks to anyone but Doug.

Beautiful Doug,

You've really got the "Field Gray Blue" down to a science. From now on I'm always going to be comparing the barrels I do to your work.

I had to take a few days off myself recently, a crack in my thumb became infected. Usually, if I catch'em early, clean, and then apply Superglue they don't get infected.

It dawned on me recently that you are possibly the "Friend in Utah" that Tony Treadwell referred to in his Blog.

Doug, those are some nice looking barrels. When you ship them back to the member, will you use some 3" PVC pipe to mail them or will you throw them into a cardboard mailing tube?

I bet that member got "the lecture" from Doug about proper shipping of barrels just like I did last year when he did my Sarriugarte barrels.

I got the same lecture again from Doug when I sent my Fox and my Remington stock to him for repair. I wouldn't trust my barrels or stocks to anyone but Doug.

Its amazing how fast he can do them too ! He was telling me this morning how easy it was and took 15 mins for the whole job !

Just kidding of course, I have told Doug several times;

"I don't know what your charging but its not enough !"

You can see the attention to every detail and how good that deep blue looks when its done.

Doug, those are some nice looking barrels. When you ship them back to the member, will you use some 3" PVC pipe to mail them or will you throw them into a cardboard mailing tube?

I bet that member got "the lecture" from Doug about proper shipping of barrels just like I did last year when he did my Sarriugarte barrels.

I got the same lecture again from Doug when I sent my Fox and my Remington stock to him for repair. I wouldn't trust my barrels or stocks to anyone but Doug.

I have it on good authority JRB that the member DID receive the lecture. Both on barrels and stocks! He's glad to hear he wasn't the only one. LOL

PA24, I installed heating elements in my tank and it certainly boils water. Only complaint is it only boils about 8" worth on each end. You don't have this issue? I'm probably going to swap the elements for longer ones.

PA24, I installed heating elements in my tank and it certainly boils water. Only complaint is it only boils about 8" worth on each end. You don't have this issue? I'm probably going to swap the elements for longer ones.

gunmaker,

You can put longer elements in your tank or just add two small additional elements low on each side. Do a little homework on what elements are available, there are quite a few out there. When it is boiling,

all the water is boiling, just not all bubbling at once, this has no negative effect on how nice the barrels blue/black. The longer it runs the more aggressive the boiling bubbles will become.

In fact my tanks bubble too aggressively and I shut down one element to slow the bubbling and alternate off/on from end to end during my rusting cycles to maintain an even water temperature.

Hope this helps.

Best Regards,

Anyone ever polish beyond 400-600 grit before rust blueing?

Anyone ever polish beyond 400-600 grit before rust blueing?

Grice, welcome aboard. I would encourage you to read through this specific thread and you will find the answer to your question.

Also this thread:

http://www.doublegunshop.com/forums/ubbthreads.php?ubb=showflat&Number=400955#Post400955

Some good stuff to be sure, especially as we will all miss PA! Still, I haven't seen any pictures which portray rust bluing as dark as that which is routinely done in Ferlach Austria...what are we missing? Steve

Mark lees provides about as dark of a black color as you are going to get.